In injection molding projects, mold costs can account for 15% to 50% of the total manufacturing budget, depending on part complexity and production volume. Sometimes, they’re unavoidable. But more often than not, they’re higher than they need to be.

There’s a real challenge: how do you reduce these costs, without sacrificing product quality or production efficiency?

In this guide, we’ll walk through the key factors that drive mold costs—and the strategies you can use to control them. Along the way, you’ll find practical examples and expert tips to help you make smarter, more cost-effective decisions.

Let’s begin with what really drives the cost of a mold.

Understanding Injection Mold Costs

Before you try to reduce mold costs, you need to understand what drives them. Injection molds are complex tools, and their cost isn’t defined by a single factor—it’s the result of several combined elements.

Here’s a breakdown of the major cost contributors you should be aware of:

1. Material Cost (20–40% of total mold cost)

The type of steel or alloy used in your mold makes a big difference in both upfront cost and long-term durability. For example, hardened steel (like H13 or S136) costs more than pre-hardened steel or aluminum, but it lasts longer under high-volume production.

Key factors that affect material cost:

- Steel grade (H13, P20, S136, 718, etc.)

- Cavity/core complexity (multi-cavity molds require more material)

- Surface finish requirements (high-polish or texture add labor and tooling)

So, while premium materials may raise initial cost, they often reduce maintenance and repair costs down the line. That’s a tradeoff worth considering.

2. Design Complexity (15–30% of total mold cost)

The more complex your part design, the more complex and expensive your mold will be. This complexity often comes from specific design features that require additional tooling steps or custom components.

For example:

- Undercuts, internal threads, or deep ribs require side actions, lifters, or collapsible cores.

- Tight tolerances demand precision machining.

- Cosmetic surfaces call for additional polishing or EDM.

Even small changes like reducing wall thickness variation or simplifying parting lines can lower the tooling cost significantly. That’s why design-for-manufacturing (DfM) analysis is crucial early in the process.

3. Manufacturing Process and Machining (20–35%)

The method used to manufacture your mold also affects the final cost. Here’s how they compare:

| Process | Best For | Cost Impact |

| CNC Machining | Most standard mold builds | Moderate |

| EDM (Electrical Discharge Machining) | Sharp corners, deep ribs, hard-to-reach areas | Higher |

| 3D Printing (e.g., conformal cooling inserts) | Complex cooling systems, prototyping | Lower (in prototyping) or Higher (inserts) |

The more machining time and setups required, the higher the cost. That’s why we recommend choosing the right method for each part of the mold. There will be a good balance between quality and expense.

4. Additional and Hidden Costs

Some costs are easy to overlook, but they still impact your total mold investment:

- Design revisions: Changes after machining starts can be costly.

- Maintenance and repair: Rust, wear, or buildup on vents can slow production or ruin parts.

- Shipping and logistics: Large molds, especially overseas, add transit and insurance costs.

- Labor and management: The more custom the mold, the more skilled labor it demands.

While these don’t always show up in the quote, they show up later—in downtime, scrap rates, or delayed deliveries.

By understanding what contributes to mold cost and how each factor affects it, you can quickly identify where cost savings are possible. In some cases, spending more upfront helps avoid greater expenses later on.

Cost Reduction Strategies: Practical Ways to Lower Mold Costs

Once you understand what drives mold costs and how each factor affects the total, the next step is to apply proven strategies to reduce those costs—without compromising performance or product quality. Below are four areas where targeted improvements can lead to measurable savings.

1. Optimize Your Design Early

Mold design is one of the most effective levers for cost reduction. Complex part geometries often require additional actions such as sliders, lifters, or multi-step machining. Simplifying the part design can reduce tooling complexity, speed up manufacturing, and lower material usage.

From our project experience in injection molding tooling and mold design, we recommend 4 practical design optimization strategies:

- Minimize unnecessary undercuts or deep cavities unless they are functionally required.

- Keep wall thickness uniform to reduce cycle times and improve part quality.

- Use consistent draft angles to ease part ejection and reduce wear on the tool.

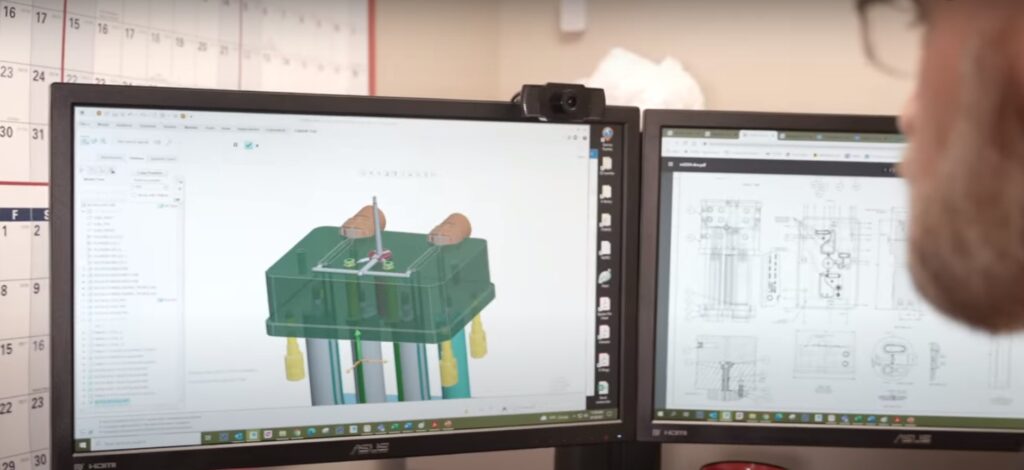

- Design with CAD tools that support manufacturability analysis, such as interference detection or core/cavity separation.

Even small changes at the design stage can avoid costly rework or tooling changes later in the process. We recommend conducting a DFM (Design for Manufacturability) review before finalizing your mold design.

2. Select Cost-Effective Materials

Material choice not only affects the part itself but also impacts tooling cost and lead time. While high-performance resins like PEEK or PSU offer excellent properties, they may require expensive tool steels and extended processing times.

To balance cost and performance:

- Use commodity plastics such as PP, PE, or PS where strength or heat resistance is not critical.

- Consider engineering-grade plastics only when required for dimensional stability, chemical resistance, or high load.

- Choose tool steels based on production volume: P20 or 718 are cost-effective for mid-volume molds; H13 or S136 are better for high-volume, long-life molds.

In our opinion, it’s more practical to match material selection with real-world performance requirements, rather than overengineering by default.

3. Choose the Right Manufacturing Process

Different mold manufacturing processes vary in cost, precision, and turnaround time. Making the right choice for each component can significantly reduce overall expenses.

Typical trade-offs include:

| Process | Advantages | Limitations |

| CNC Machining | High accuracy, widely available, affordable | May struggle with deep or sharp features |

| EDM (Electric Discharge Machining) | Ideal for complex geometries, sharp corners | Slower and more costly |

| 3D Printing (Inserts or Prototyping) | Low-cost for testing and cooling channels | Not suitable for final hardened tooling |

For standard mold features, we recommend CNC machining due to its balance of cost, speed, and precision. EDM is reserved for features that cannot be achieved through traditional machining. In prototyping or complex cooling systems, 3D-printed inserts may offer both time and cost advantages.

4. Plan for Maintenance from the Start

Tool maintenance is often overlooked when calculating mold costs. However, unexpected downtime, surface wear, or part defects caused by poor maintenance can lead to serious expenses later in production.

To control long-term maintenance costs:

- Design molds with accessible components to simplify inspection and cleaning.

- Lubricate moving parts regularly to prevent friction damage.

- Schedule preventive maintenance based on cycle counts or production intervals.

- Use corrosion-resistant materials when molds operate in humid or chemically aggressive environments.

We’ve seen that a structured maintenance plan can reduce repair costs by up to 30% over a mold’s lifecycle. It also ensures more consistent part quality and longer tool life.

These strategies are most effective when applied early in the project—ideally during design and supplier discussions. By focusing on simplification, material choice, efficient tooling methods, and long-term planning, you can significantly reduce mold costs while maintaining quality and performance.

Real-World Case Insights: How Companies Reduce Mold Costs

Below are two real-world examples from our past projects. They demonstrate how even small, well-placed changes can result in substantial savings in mold-related costs.

Case 1: Simplifying Design Geometry Reduced Tooling Cost by 28%

Client: European electronics OEM

Project: Multi-cavity mold for consumer device housings

Initial issue: The original part design included multiple undercuts, sharp internal corners, and varying wall thicknesses. The mold quote came in 42% above the client’s target budget.

What we did:

- Removed one undercut and replaced it with a snap-fit redesign

- Standardized wall thickness from 2.0–2.8mm to a uniform 2.4mm

- Added consistent 2° draft angles to vertical walls

- Converted sharp internal corners to fillets (R0.5–R1.0)

Results:

- Tooling complexity reduced: fewer side actions and core pulls

- Mold cost reduced by 28%

- Part aesthetics maintained; structural performance improved due to uniform stress distribution

- Lead time shortened by 10 working days

This case showed that design changes do not need to compromise functionality. You just need to rethink the approach with manufacturing in mind.

Case 2: Material Reselection Saved Over $18,000 per Year

Client: US-based industrial supplier

Project: Mold for a mid-volume gear housing used in warehouse automation

Initial issue: The original material was a high-performance glass-filled nylon rated for -40°C, which exceeded actual field requirements.

What we did:

- Conducted load + thermal simulation on the expected use environment

- Identified that PP + 10% glass fiber could meet specs with a lower tooling wear profile

- Coordinated a test mold to validate shrinkage, flow, and warpage

Results:

- Material cost per part reduced by 37%

- Tool steel grade downgraded from H13 to 718—lower machining cost and faster delivery

- The annual mold wear repair budget dropped by ~25%

- Estimated annual savings: $18,400 across 90,000 parts/year

By choosing material for the actual job rather than the worst-case scenario, we helped the client cut costs without cutting reliability.

Key Takeaways

- Design simplification can remove expensive mold features without affecting function

- Material choice has downstream effects on tooling, processing, and lifespan

- The biggest cost savings often come from understanding what is truly necessary—and what isn’t

Real savings don’t always require a new vendor or a cheaper mold shop. Sometimes, they just require better decisions earlier in the project.

How to Choose the Right Mold Maker

Choosing a mold supplier isn’t just about comparing prices. It’s about identifying a partner who can deliver consistent quality, meet deadlines, and stay transparent about costs. Below are three practical considerations to guide your supplier evaluation process.

1. Evaluate Whether the Quotation Is Realistic

A mold quote that looks attractive on paper may not hold up under production realities. To assess whether a quote is reasonable:

- Break down the cost structure. A credible supplier should provide itemized pricing—base mold cost, steel type, cavity/core details, machining time, surface treatments, and lead time.

- Compare with past project benchmarks. Use previous tooling costs (if available) for similar part sizes and complexity as a reference point.

- Look at what’s included—and what’s not. A lower quote may exclude essential elements like first article inspection (FAI), T1 revisions, or mold trials.

Tip: If one supplier’s quote is significantly lower than the others (20%+), question what’s missing before assuming it’s a better deal.

2. Watch for Hidden Costs

What looks like a cost advantage upfront can turn into unexpected expenses later if you’re not careful. Common hidden costs include:

- Engineering changes billed separately after mold kick-off

- Limited free revisions, after which every adjustment incurs a charge

- Inadequate steel spec, leading to faster wear and higher long-term maintenance

- Exclusions of shipping, taxes, or mold trial fees in the initial quote

Ask for a full quotation scope that clearly states:

- How many DFM iterations are included

- Whether first mold trials (T0, T1) are included

- Shipping terms (FOB, EXW, DDP) and who bears logistics risk

- Warranty or service terms for mold maintenance post-delivery

Our experience: Projects with unclear quotation scope often incur 10–15% more in follow-up charges than those with fully scoped, upfront pricing.

3. Communicate Expectations Upfront

Cost issues often arise not from pricing itself, but from misaligned expectations. Clear early communication helps ensure that quality and budget stay on track.

- Define acceptable tolerances, material specs, and surface finishes before quotation.

- Share product usage conditions (e.g., outdoor exposure, high load) that may affect mold steel selection.

- State volume projections and lifetime shot expectations, as they influence mold class and pricing.

Make sure your supplier confirms:

- Mold classification standard (e.g., SPI Class 101, 102)

- Target cycle time

- Expected number of reworks or design loops

- Who provides final approval for the design freeze

A capable mold supplier should ask these questions proactively. If they don’t, that’s a red flag.

Don’t treat mold sourcing as a price comparison exercise. The right supplier will not just match your spec—they’ll help you refine it, flag cost risks early, and build tools that last. Choose based on clarity, process, and trust, not just the number on the quote sheet.

Expert Insights: Best Practices for Controlling Mold Costs

After supporting hundreds of mold development projects across industries—from automotive to consumer electronics—we’ve seen where costs creep in and how leading manufacturers avoid them. Below are five best practices we consistently recommend to clients looking to keep mold costs under control without compromising quality or long-term performance.

1. Involve DfM Reviews Before Quoting

Too many cost issues stem from quoting a design that isn’t optimized for molding.

We recommend conducting a DfM (Design for Manufacturability) review before you request quotes. This allows you to simplify part geometry, eliminate undercuts, and reduce wall thickness variation—often cutting tooling costs by 15–30% from the start.

Expert note: A 30-minute DFM review before quoting can save weeks of revisions and thousands in rework later.

2. Specify the Mold Class Based on Part Volume

Mold class directly affects steel grade, cooling design, and cost. Yet many buyers don’t specify it clearly.

Use industry standards (e.g., SPI Class 101–105) to align your mold’s durability with your production volume and lifecycle goals.

- Low-volume (<10K shots)? Class 103 mold may be enough.

- High-volume (>500K shots)? Class 101 with hardened steel is essential.

Expert note: Over-specifying leads to overspending. Under-specifying leads to tool failure.

3. Standardize Components Where Possible

Customized components increase machining time, setup complexity, and replacement costs.

Whenever possible, use standardized ejector pins, base plates, and guide elements from major mold base suppliers (e.g., DME, HASCO).

Our benchmark: Standardization can reduce both initial cost and future downtime—up to 20% faster replacements during maintenance.

4. Negotiate for Lifetime Support Terms Upfront

Most mold failures happen during long-term use, not initial runs. Ask suppliers to specify:

- Free maintenance periods

- Cost for wear-and-tear replacements

- Lead time for part replacements

Include this in your contract—don’t assume it’s covered.

Expert tip: A mold that costs $2,000 less but comes with no post-sale support can become more expensive within 12 months.

5. Track Total Cost of Ownership (TCO), Not Just Initial Price

Smart buyers look beyond the quote. Include the following in your cost model:

- Mold maintenance schedule and cost

- Downtime risk and recovery plans

- Scrap rates from early runs

- Engineering change costs after design freeze

This helps you avoid short-term savings that lead to long-term losses.

Final Advice from the Field:

The best-performing companies treat mold sourcing as a strategic process, not a purchasing task. They involve engineering early, document expectations clearly, and evaluate suppliers by transparency—not just price.

We’ve seen it repeatedly: the most expensive molds are often those that looked “cheapest” at the start.

Reduce Mold Costs the Smart Way

Too often, teams treat mold cost as a number to push down—without asking what drives it in the first place. But the most cost-effective projects we’ve seen aren’t the ones with the cheapest quotes. They’re the ones where decisions were made early, deliberately, and with the full lifecycle in mind.

Design, materials, manufacturing methods—each plays a role. And none of them work well in isolation.

If you’re planning a new molding project or re-evaluating an existing one, we’re here to help. Contact our team for a free design review or cost evaluation.

FAQs about Mold Cost

How much does an injection mold typically cost?

Injection mold costs can range from $2,000 to over $100,000, depending on factors such as:

- Part complexity: More intricate designs require more machining and features like lifters or slides.

- Number of cavities: Multi-cavity molds cost more but lower per-part cost in high-volume runs.

- Mold material: Aluminum molds are cheaper but less durable; hardened steel molds last longer.

- Tolerances and surface finish: Tight tolerances or polished surfaces increase cost.

For most standard plastic parts, a production-grade mold usually costs between $5,000 and $20,000.

What’s the best way to evaluate if a mold quote is reasonable?

Start by asking for a detailed cost breakdown—covering design, steel material, machining time, number of cavities, and surface finishing. A transparent quote helps you spot inflated or missing charges.

Next, compare the quote against:

- Your part’s complexity – Complex geometry, tight tolerances, or undercuts will naturally raise cost.

- Expected production volume – A high upfront cost may be justified if the mold supports long-term use.

- Supplier’s experience and tooling standards – Check if the quote includes mold class specification, revision support, or post-sales service.

Finally, don’t hesitate to get a second opinion. An experienced tooling partner can help you identify red flags and validate whether the cost aligns with your goals.

What questions should I ask my mold supplier to ensure cost control?

To keep mold costs under control without compromising quality, here are the key questions to ask your supplier:

- Can you suggest design changes to simplify the mold and reduce tooling cost?

(E.g., minimizing undercuts, standardizing wall thickness) - Which mold class and steel grade do you recommend—and why?

Ensure it matches your production volume, not over- or under-specified. - Are there any features in my current design that are driving up cost unnecessarily?

- What’s the impact of using a single-cavity vs. multi-cavity mold in my case?

- Is there a more cost-effective gating or runner system for this part?

(E.g., hot runner vs. cold runner, direct vs. side gating) - What’s included in the quote, and what might incur extra charges later?

Clarify design iterations, sampling, shipping, and mold modifications. - Can you provide a breakdown of the mold cost (design, machining, materials, etc.)?

- Do you offer DFM analysis or cost-saving recommendations during the design stage?

✅ Pro tip: Sending part files (STEP/IGES), volume estimates, and performance requirements along with these questions will help suppliers quote faster and more accurately.

What is the SPI mold classification system, and why does it matter?

The SPI mold classification system—developed by the Plastics Industry Association—categorizes molds into five classes (Class 101 to Class 105) based on their intended use, durability, and expected production volume.

The 5 SPI Mold Classes:

| Class | Typical Use | Expected Cycles | Notes |

| 101 | High-volume production | 1,000,000+ | Built for maximum durability; highest cost |

| 102 | Medium to high-volume | Up to 1,000,000 | Hard tool steel; long service life |

| 103 | Medium-volume | Under 500,000 | Common for general-purpose molds |

| 104 | Low-volume or limited runs | Under 100,000 | Lower upfront cost; shorter lifespan |

| 105 | Prototype or short-run only | Under 500 | Least durable; not for long-term use |

Why It Matters:

- It helps you align mold cost with production needs, avoiding overengineering or underperforming tools.

- It gives you a standardized reference when comparing quotes across suppliers.

- It affects key specs like steel type, surface finish, cooling system, and maintenance expectations.

Pro tip: Always confirm which SPI class your supplier is quoting. A lower-cost quote may reflect a lower mold class, unsuitable for long-term use.

What materials are most cost-effective for injection molds?

The most cost-effective mold materials strike a balance between initial tooling cost, durability, and production volume requirements. Here’s a quick overview:

Common Mold Materials & Their Cost-Effectiveness:

| Material | Cost | Durability | Typical Use Case |

| Aluminum | Low | Low–Medium | Prototypes, short runs (Class 105/104) |

| P20 Steel | Moderate | Medium | General-purpose molds (Class 103/102) |

| H13 Steel | Higher | High (heat-resistant) | High-volume molds, engineering plastics |

| S136 Steel | High | Very High (corrosion-resistant) | Medical, optical, or high-finish parts |

| NAK80 | Moderate–High | High (pre-hardened) | Cosmetic parts, mirror polishing |

Cost-Saving Tips:

- Use aluminum for short-run or prototype molds where long life isn’t required.

- P20 is a widely used, cost-effective option for moderate-volume production.

- Avoid over-specifying: don’t use hardened steels like S136 unless corrosion resistance or ultra-long life is critical.

Choosing the right material isn’t just about price—it’s about matching your tool to the part’s function, finish, and production lifecycle.