TDL: Leading Company of Plastic Injection Molding in China!

TDL offers full custom mold design, mold manufacturing, and plastic injection molding services for automotive, medical, electronics, and consumer goods industries.

About TDL

Who We Are

TDL is an experienced injection molding company in Dongguan, Guangdong, China. Established in 1995, covering 6500 square meters, we have delivered mold making & plastic injection molding services for 2,000+ clients around the world.

- Over 28 years of experience in mold making and injection molding

- In-house mold design and manufacturing

- Supports both small and large batch production

- Strong professional team, including 34 senior engineers and 12 designers

What We Do

On-demand Manufacturing Services

Learn more about our Capabilities

TDL Robust Capabilities Behind Numbers

Diverse Industry Solutions

Medical molds

Specialized innovations focused in meeting the unique needs of the medical industry

Electric & Electronics

Specialized molds for complex electric and electronics applications.

Products

What Plastic Parts Have We Produced?

Advantages

Why Choose TDL for Custom Injection Molding?

20 + Years Experience

For over 20 years, TDL mould has excelled in creating injection molding tools for the automotive, medical device, and electronics industries.

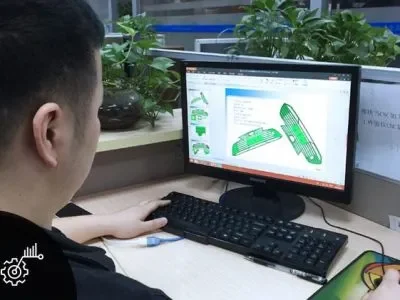

Advanced Equipment

TDL factory is equipped with advanced mold manufacturing equipment and precision measuring instruments CMM.

On-Time Delivery

TDL schedule every mold projects manufacturing process very well, can guarantee on-time delivery for each production.

Professional Team

TDL mold design & engineering team has 34 skilled engineers to provide technical support for plastic mold making and plastic processing.

One-Stop Solution

TDL offers one stop solution to meet customers all demands about plastic mould and customized plastic products manufacturing.

Good After-sales Service

TDL is responsible for quality of each mold, will sign mold quality warranty with customers for every tools.

How to Work With Us

Submit Project Requirements

Upload your 3D CAD file or provide technical drawings, and let us know your production requirements (such as materials, quantity, and process specifications).

Supported file formats: STEP, IGES, STL, etc.

Project Evaluation & Quotation

DFM Analysis: Provide design optimization recommendations to ensure smooth production.

Detailed Quotation: Transparent cost analysis and delivery timeline.

Production & Processing

Mold Design & Manufacturing: High-precision mold fabrication.

Comprehensive Processing Services: Injection molding, CNC precision machining, 3D printing, and other processes.

Delivery & After-Sales Support

On-Time Delivery: Fast response and timely delivery.

Ongoing Support: We provide mold maintenance, design updates, and repeat production services to ensure a stable, long-term supply.

Case Studies

How Does TDL Achieve Precision in Automotive Door Handle Mold Manufacturing?

TDL excels in automotive door handle mold manufacturing by leveraging advanced technology and innovative solutions. They meet stringent client requirements for precision, quality, and short lead times through meticulous design, mold flow analysis, and rigorous quality control, ensuring superior performance and aesthetic standards.

Our Equipment

CMM

Inspection

High Speed CNC Machines

Double-Head EDM Machines

EDM

Workshop

CNC machining Workshop

Plastic Injection Molding Room

Mirror EDM Machining

Mould Spotting Machine

Meet Us In Trade Shows

2012 NPE USA

2014 IRANPLAST exhibition

2021 ChinaPlas

2012 NPE USA

2016 K exhibition Germany

2024 NPE USA

Some of our customers

Testimonials

What our customer say

From start to finish, the team at TDL was knowledgeable, professional, and extremely helpful. They took the time to understand my needs and worked with me every step of the way to ensure that the final product was exactly what I wanted. The mold they created was of the highest quality and has held up perfectly over multiple runs.

Mike Kendricks

Customer