CNC turning and CNC milling are often mentioned together — they are two of the most widely used machining processes in modern manufacturing. Both rely on computer-controlled cutting to achieve precision and repeatability, but they are not interchangeable. Each process is suited to specific geometries, tolerances, and production needs.

Choosing the wrong process can lead to higher costs, longer lead times, or parts that fail to meet functional requirements. Understanding the fundamental differences between turning and milling helps you make informed decisions, ensuring that each project is matched with the most efficient and cost-effective method. This article will walk you through how the two processes work, where they differ, and when each is the better option.

What Is CNC Turning?

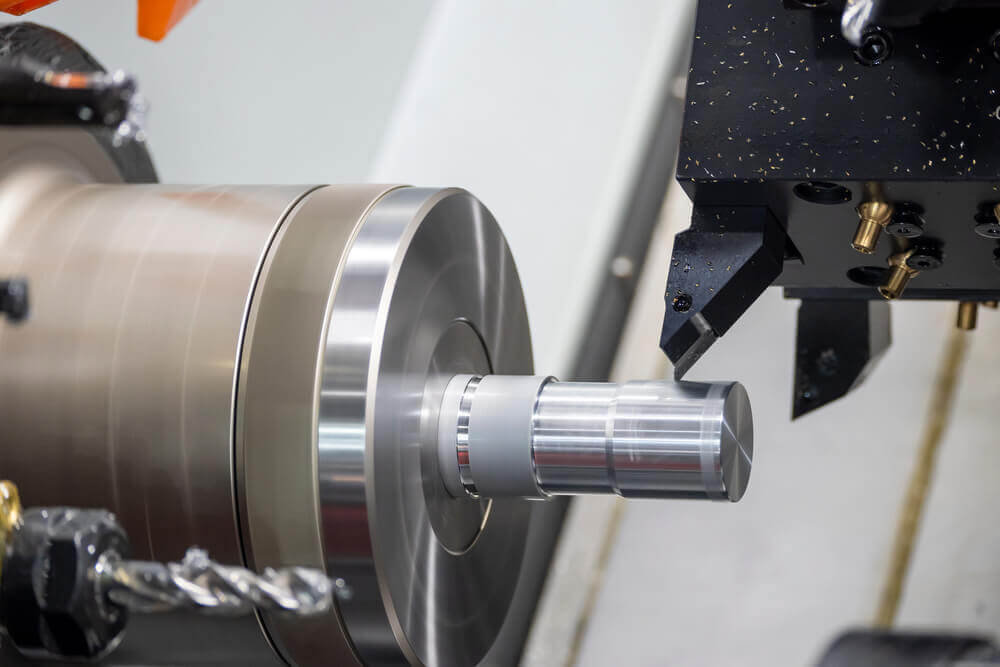

CNC turning is a machining process where the workpiece itself rotates at high speed while a stationary cutting tool removes material. This fundamental difference—rotating the part instead of the tool—makes turning especially effective for creating round and symmetrical components.

Turning shines when you need parts like shafts, pins, bushings, or threaded connectors. These are not just common shapes; they’re building blocks in industries ranging from automotive drivetrains to aerospace fasteners. Because the material spins, the tool can cut consistent diameters and achieve excellent concentricity, something that is harder to match with milling.

Another practical strength of turning is efficiency in volume production. Once a lathe is set up, it can produce hundreds or thousands of identical parts with minimal variation. Cycle times are often shorter than milling for cylindrical parts, because the toolpath is simple and material removal is highly controlled.

Precision is also a key factor. Modern CNC lathes routinely achieve tolerances in the micrometer range, making them suitable for critical applications such as hydraulic components or medical implants, where both fit and finish determine performance.

In short, CNC turning is the process you turn to when accuracy on round geometries, fast repeatability, and high throughput are non-negotiable.

What Is CNC Milling?

CNC milling takes the opposite approach of turning: here, the cutting tool rotates at high speed while the workpiece is held stationary or moved along programmed paths. This setup makes milling especially versatile for shaping parts with flat surfaces, angled features, slots, pockets, or complex 3D contours.

Where milling really proves its value is in handling geometries that cannot be achieved on a lathe. For example, think of a heat sink with multiple fins, a pump housing with intersecting channels, or a custom bracket with angled pockets. These parts demand multi-axis tool movement, something milling machines are designed to deliver.

Flexibility is another strength. With modern 3-axis and 5-axis milling centers, you can cut features from different orientations in a single setup, reducing the need for multiple machines or manual repositioning. That not only saves time but also improves accuracy, since fewer clamping operations mean fewer chances for error.

Milling is also well-suited for prototypes or lower-volume production runs. Because the same machine can be programmed to cut different part geometries, you can shift quickly from one design to another without investing in specialized tooling. This agility makes milling the go-to process when designs are still evolving or when part complexity outweighs batch size.

In essence, CNC milling is the process you choose when the part calls for flatness, angles, slots, or freeform geometry—features that turning simply cannot produce with the same efficiency or precision.

CNC Turning vs CNC Milling: Core Differences

Although both processes fall under CNC machining, they solve different kinds of problems. Understanding these differences helps you match the method to your part requirements instead of treating them as interchangeable.

| Aspect | CNC Turning | CNC Milling | Why It Matters |

| Motion Principle | Workpiece rotates, tool is fixed | Tool rotates, workpiece moves or stays fixed | This defines what geometries can be cut efficiently |

| Typical Geometries | Cylindrical, conical, threaded, round features | Flat surfaces, slots, pockets, angled or complex 3D shapes | Each process specializes in different core shapes |

| Part Examples | Shafts, pins, bushings, couplings | Housings, brackets, heat sinks, molds | Quick mental check: round = turning, prismatic = milling |

| Efficiency | High efficiency for symmetric parts, short cycle times | Efficient for multi-feature parts in fewer setups | Helps you evaluate cost per part at scale |

| Precision & Tolerances | Excellent concentricity and surface finish on round parts | High accuracy on complex contours and multi-axis features | Choose based on what dimension is most critical |

| Cost & Volume Fit | Lower per-part cost in large batches of simple geometries | More flexible for prototypes and low–mid volumes of complex parts | Influences whether you invest in dedicated tooling or keep designs flexible |

Turning excels at precision and speed for round parts, while milling delivers flexibility for complex geometries. In practice, many projects combine both—using turning to create the base cylindrical form, then milling to add secondary features.

When to Use CNC Turning

CNC turning is the process you rely on when precision around a central axis is critical. If your part is essentially round or symmetrical, a lathe will almost always be the most efficient and cost-effective choice.

1. Shafts, Pins, and Bushings

Shafts, pins, and bushings are classic examples. These parts demand concentricity, smooth surfaces, and tight tolerances along their length. A turning operation can produce them faster and with better repeatability than any milling setup.

2. High-Volume Production

Turning also makes sense when you’re running high volumes of identical parts. Once the lathe is dialed in, cycle times are short and consistent, making it ideal for automotive, aerospace, or industrial applications where thousands of parts must be identical.

3. Superior Surface Finish

Another common reason to choose turning is surface finish requirements. Because the cutting action follows the rotation of the material, lathes can achieve excellent surface smoothness, which is important for sealing surfaces, bearing fits, or threaded features.

In short, if your part is primarily cylindrical, must be produced in volume, or needs outstanding concentricity and finish, CNC turning is the process that delivers the best results.

When to Use CNC Milling

CNC milling is the process you choose when your design goes beyond simple cylindrical shapes. It provides the flexibility to create flat surfaces, angled cuts, and complex geometries that lathes cannot handle efficiently.

1. Complex or Asymmetric Geometries

Milling is ideal for components that are not rotationally symmetrical. Think of brackets, housings, or casings with pockets, grooves, and angled faces. These shapes require multi-axis tool movement, which is where milling excels.

2. Features Like Slots, Holes, and Pockets

Whenever your part design includes internal cavities, surface slots, or precision holes, milling is the right option. With a single setup, a CNC mill can cut multiple features from different orientations, saving both time and alignment errors.

3. Low- to Medium-Volume Runs

Milling is especially practical for prototypes or smaller production batches. Because it does not require custom fixturing or specialized tooling for each geometry, you can shift quickly from one design to another. This agility makes milling cost-effective when parts are still evolving or demand is unpredictable.

When your design involves irregular geometry, multiple features, or lower production volumes, CNC milling provides the flexibility and precision you need.

Real-World Application Examples

Sometimes, the easiest way to see the difference between CNC turning and CNC milling is by looking at actual parts in use. Here are two clear examples from different industries.

1. Automotive Components

A drive shaft is a classic turning job. It’s long, cylindrical, and must maintain strict concentricity so it can rotate smoothly without vibration. A CNC lathe can machine it quickly and deliver the required precision.

By contrast, an engine housing is a milling job. It involves intersecting channels, mounting surfaces, and cavities for other components. These complex geometries demand multi-axis tool movement, which a CNC mill handles far more efficiently than a lathe.

2. Electronics Parts

A small connector pin is ideal for turning. It’s round, requires threading, and benefits from the excellent surface finish that lathes provide. Producing thousands of identical pins is fast and cost-effective on a turning center.

A heat sink enclosure, on the other hand, belongs to milling. It requires flat fins, drilled holes, and precise cutouts for airflow and mounting. Only a milling machine can create those pockets and flat geometries with the required accuracy.

These examples highlight a simple rule of thumb: if it’s primarily cylindrical, think turning; if it’s prismatic or complex, think milling.

Cost and Efficiency Considerations

When you compare CNC turning and milling, the choice is not just about geometry—it also has a direct impact on cost and throughput.

Turning: Lower Cost for High Volumes

Turning is highly efficient when producing large numbers of cylindrical parts. Cycle times are short because the toolpaths are simple and repetitive, and material removal is controlled. For shafts, pins, or threaded connectors, this translates into lower cost per part once the machine is set up.

Milling: Flexibility Reduces Setup Waste

Milling may not always match turning’s speed on round parts, but it saves time and cost when you need to machine multiple features in a single setup. Complex housings, brackets, or casings can be completed on one machine without moving between stations, cutting down both labor and error risk. For prototypes or low- to mid-volume runs, this flexibility often outweighs raw cycle time.

Combining Both Processes

In many real projects, the most efficient route is not choosing one or the other, but combining them. A part might first be turned to create its cylindrical base, then transferred to a mill to add pockets or mounting features. This hybrid approach balances speed, precision, and feature complexity.

How to Choose the Right Process for Your Project

Choosing between CNC turning and milling usually starts with one simple question: what does your part actually look like? If the design is dominated by cylindrical features—like a shaft, a pin, or a threaded rod—turning almost always delivers faster cycles, tighter concentricity, and lower per-part costs at scale. But when the part has flat faces, intersecting slots, or irregular pockets, milling is usually the smarter path, because it gives you the flexibility to create those shapes without excessive setups.

Volume also plays a role. For high-throughput production where every second on the machine matters, turning’s efficiency on rotational parts can’t be matched. If you’re only making a handful of parts or still refining a prototype, milling’s adaptability saves you from costly retooling. Precision requirements can tip the balance too: if the critical dimension is a round bearing fit, turning is the safer choice; if it’s the alignment of multiple planar surfaces, milling provides the control you need.

By weighing geometry, volume, precision, and early input from your supplier, you can choose the process that delivers the best balance of cost, speed, and quality.

Conclusion: Matching Process to Part Requirements

Turning delivers speed and consistency for cylindrical parts where concentricity and smooth finishes are essential. Milling brings flexibility, making it possible to create flat surfaces, pockets, and complex geometries in a single setup.

If you want to avoid unnecessary costs or delays, the key is to involve your manufacturing partner early. With their input, you can confirm whether turning, milling, or a mix of both is the most efficient path forward. That collaboration helps you move from design to production with fewer surprises—and ensures your parts are delivered on time, on budget, and to the standard your project demands.