Plastic Injection Molding Services

No MOQ | DFM Support | ISO 9001 Certified

TDL: Professional Partner of Plastic Injection Molding Services in China!

As a source factory, TDL has over 25 years of rich experience in mold manufacturing and injection molding, dedicated to providing customers with one-stop solutions from design to production.

Injection Molding Services

Plastic Injection Molding

Plastic injection molding is a widely used manufacturing process for large-scale production. This molding process involves melting plastic materials and injecting the molten plastic into precisely designed molds, where it cools and solidifies into the desired parts.

- High-volume production

- Precise dimensional control

- Ability to produce complex shapes

Overmolding is a manufacturing process where another material is injected onto an already molding part. This technique can be used to manufacture two-color or multi-layer products, such as commonly seen two-color toys or plastic products with soft rubber grips.

- Combines the benefits of multiple materials to enhance functionality.

- Ability to enable multi-color designs and complex part aesthetics.

Insert molding is an injection molding process where pre-processed metal, ceramic, or plastic components are inserted into the mold cavity, and molten plastic is injected to encapsulate and form the part, bonding the insert with the plastic to create a unified component.

- Function Integration: Solves challenges beyond single-material capabilities.

- Design Flexibility: Ability to enable complex, lightweight structures.

Injection Molding Capabilities

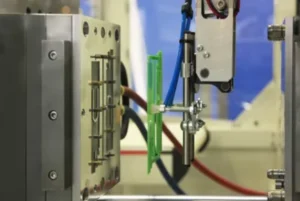

Inside TDL’s Injection Molding Factory

Taking a closer look at how our automated production lines, precision equipment, and experienced engineers work together to deliver high-quality molded parts with speed and consistency.

Capabilities | Specifications |

Lead Time | Mold Design delivery: 3-6 weeks; Sample Trial: 5 business days after confirmation; Mass Production: delivery based on order quantity, as fast as 3 days. |

Production Options | Support both domestic and international production; flexible batch production, offering small batch prototyping and large-scale production services. |

Materials | Handle various plastics: ABS, PC, POM, PA; high-performance materials: PEEK, PPS, LCP; eco-friendly materials: biodegradable plastics. |

Machines Available | Injection molding machines ranging from 30 to 2,000 tons, supporting single-cavity molds, multi-cavity molds, and family molds; equipped with automated production lines and side-action mechanisms. |

Inspection & Certification | Compliance with AS9100, ISO 9001, and ISO 13485 standards; provides FAI and PPAP documentation; supports cleanroom molding (ISO Class 7 and 8). |

Tool Ownership | Customer-owned molds with lifetime maintenance services to ensure long-term efficiency and stability. |

Tolerances | Mold cavity tolerances: ±0.005mm; part-to-part repeatability: ±0.004mm; critical feature tolerances: higher precision available upon request. |

Available Mold Types | Mold types: steel molds (Class 101 to 105), aluminum molds (from prototype to high-production molds); support for complex cooling designs and high-gloss surface finishes. |

We are ready to support you with custom injection molding services. Contact us to get a quote or discuss your project requirements.

Injection Molding Capabilities

Capabilities | Specifications |

Lead Time | Mold Design delivery: 3-6 weeks; Sample Trial: 5 business days after confirmation; Mass Production: delivery based on order quantity, as fast as 3 days. |

Production Options | Support both domestic and international production; flexible batch production, offering small batch prototyping and large-scale production services. |

Materials | Handle various plastics: ABS, PC, POM, PA; high-performance materials: PEEK, PPS, LCP; eco-friendly materials: biodegradable plastics. |

Machines Available | Injection molding machines ranging from 30 to 2,000 tons, supporting single-cavity molds, multi-cavity molds, and family molds; equipped with automated production lines and side-action mechanisms. |

Inspection & Certification | Compliance with AS9100, ISO 9001, and ISO 13485 standards; provides FAI and PPAP documentation; supports cleanroom molding (ISO Class 7 and 8). |

Tool Ownership | Customer-owned molds with lifetime maintenance services to ensure long-term efficiency and stability. |

Tolerances | Mold cavity tolerances: ±0.005mm; part-to-part repeatability: ±0.004mm; critical feature tolerances: higher precision available upon request. |

Available Mold Types | Mold types: steel molds (Class 101 to 105), aluminum molds (from prototype to high-production molds); support for complex cooling designs and high-gloss surface finishes. |

We are ready to support you with custom injection molding services. Contact us to get a quote or discuss your project requirements.

Wide Selection of Molding Materials

Our extensive material library includes over 100 thermoplastics and thermoset options, providing plastic molding solutions tailored to specific application needs and industry standards.

Polypropylene (PP)

- Lightweight and flexible.

- Excellent chemical resistance and cost-effective.

Applications: Packaging, automotive parts, household products.

Polyethylene (PE)

- High impact strength and durability.

- Superior moisture resistance and chemical tolerance.

Applications: Containers, pipes, consumer goods.

ABS

- High strength, rigidity, and lightweight.

- Good impact resistance and surface finish.

Applications: Electronic housings, automotive trims, toys.

Polycarbonate (PC)

- High strength and wear resistance.

- Low friction and strong chemical resistance.

Applications: Gears, bearings, structural parts.

Nylon (PA)

- High clarity and impact resistance.

- Excellent dimensional stability and heat resistance.

Applications: Optical lenses, medical devices, automotive components.

Polystyrene (PS)

- Rigid, lightweight, and easy to mold. Ideal for mass production and cost-effective.

- Ideal for mass production and cost-effective.

Applications: Disposable containers, packaging, appliances.

Polyoxymethylene (POM)

- Outstanding dimensional stability and low friction.

- High wear resistance and chemical durability.

Applications: Precision parts, gears, fasteners.

Thermoplastic Elastomers (TPE)

- Highly flexible with rubber-like properties.

- Easy to process and customizable.

Applications: Handles, seals, flexible components.

High-Performance Plastics

- Materials like PEEK, PPS, and LCP for extreme conditions.

Applications: Aerospace, medical, and high-end electronics.

Our engineering team offers professional support for material selection.

Read our injection molding material selection guide to learn more.

Secondary Processing Services

Are your injection molded parts facing the following challenges?

- Rough surface or monotonous color

- Limited functionality (e.g., unmet requirements for conductivity, anti-slip, etc.)

- Need for high-precision structural corrections or complex assembly

As a one-stop injection molding service provider, we offer comprehensive secondary processing solutions.

Service Category | Processes | Core Benefits | Application Fields |

1. Surface Treatment | Spraying, Electroplating, Vacuum Coating, Laser Engraving | • Appearance Enhancement: Matte/Metallic/Gradient textures • Durability: Scratch-resistant, UV-proof • Functional Additions: Conductive coatings, Fingerprint resistance | • Home Appliance Housings • Automotive Accessories • Electronic Products • Cosmetic Packaging |

2. Structural Optimization | CNC Precision Machining, Ultrasonic Welding, Heat Treatment | • Defect Correction: Deburring, Dimensional accuracy • Complex Structure: Insert assembly, Custom cavities • Material Stability: Stress relief | • Medical Devices • Precision Molds • Drone Components • Automotive Parts |

3. Functional Additions | Chemical Etching, Conductive Ink Printing, Micro-foaming | • Micro-structures: Micro-porous filters, Circuit patterns • Property Enhancement: Conductivity, Shock-absorption • Surface Modification: Anti-slip, Antibacterial | • Consumer Electronics • Industrial Filters • Baby Products • Sports Equipment |

4. Assembly & Packaging | Component Assembly, Labeling, Vacuum Packaging | • Final Integration: Complete product assembly • Transport Safety: Shockproof packaging • Efficiency: Streamlined post-processing | • Toys • Food Containers • Smart Home Devices • 3C Products (Computers, Communication, Consumption) |

Surface Finishing for Your Parts

Post-injection surface treatment can enhance the appearance and performance of products.

Spraying Process

Coating Types: Epoxy resin, polyurethane, UV-curable coatings

Coating Thickness: 10–50 μm (matte/gloss/gradient finishes available)

Electroplating

Metal Plating Layers: Nickel, chromium, zinc, copper (thickness: 0.5–5 μm)

Pre-treatment: Chemical conductive treatment (to address plastic insulation issues)

Vacuum Coating

Film Types: Aluminum, magnesium, ITO (conductive film)

Film Thickness Control: 0.1–1 μm (lightweight, transparency >90%)

Laser Engraving

Precision: ±0.01 mm (micron-level machining)

Material Compatibility: Acrylic, PC, PETG

Contact us for expert recommendations on suitable surface treatment solutions for different materials!

Why Choose TDL for Plastic Injection Molding?

No MOQ

We support small batch production with a low MOQ ranging from 1 to 100 pieces, enabling quick responses to diverse, small-volume demands.

Strong Production Capacity

Equipped with 75 injection molding machines and 80 sets of molds, we cover the entire process from mold development to finished product assembly, offering flexibility to handle both large and small orders.

Global Standard Quality

Certified with ISO 9001, ISO 14001, and ISO 13485, and currently applying for IATF 16949 certification. Our products comply with RoHS, REACH, and other standards.

Efficient Delivery Performance

With a 98.5% on-time delivery rate, we ensure reliable and punctual deliveries, guaranteeing that projects are completed on schedule.

Professional Team Support

Our team includes 36 mold engineers with an average of 15 years of experience, and our chief engineer has 25 years of experience. We provide full technical support throughout the entire process.

Comprehensive After-Sales Service

We offer product defect repair, replacement, annual on-site services, and 24/7 customer support to ensure customers are worry-free.

TDL vs Other Injection Molding Companies

While many companies provide only basic injection molding services, TDL delivers the one-stop plastic molding solution — from mold design to surface finishing and assembly.

Other injection molding factories

- Unable to design moulds

- Only provide injection molding

- Complex communication

- Mould issues require back-and-forth communication

- Slow response

- Time-consuming

Our injection molding service

- One-stop service

- Capable of both injection molding and mould design

- Surface treatment, Assembly & Packaging

- Saving communication and transportation costs

- Quick response

- Cost-effective for customers

- Saves mould costs

How to Work with Us?

Design Submission & Evaluation

Submit your design files for feasibility assessment and initial project review.

Quotation & Project Planning

Receive a detailed quotation within 48 hours, including tooling, production cost, and lead time.

DFM Analysis & Approval

Get a full DFM (Design for Manufacturability) report and confirm the mold design before fabrication.

Mold Fabrication

The mold is manufactured in-house with precision machining and strict quality inspection before trial.

T1 Sample Verification

Conduct the first mold trial (T1) and provide samples for client approval and possible adjustments.

Mass Production & Quality Control

Proceed to large-scale production after sample approval, ensuring consistent quality through inspection.

On-Time Delivery & After-Sales Support

Deliver products on time with full logistics tracking and provide continuous technical support.

We support CAD, STL, STEP, and IGES formats. Contact us if you encounter any upload issues.

Choose us for injection molding and get up to 100% mould cost refund!

Injection Molding Case Studies

Explore how TDL has provided custom injection molding services across industries — from automotive components to electronic housings and consumer products.

How Does TDL Achieve Precision in Automotive Door Handle Mold Manufacturing?

TDL excels in automotive door handle mold manufacturing by leveraging advanced technology and innovative solutions. They meet stringent client requirements for precision, quality, and short lead times through meticulous design, mold flow analysis, and rigorous quality control, ensuring superior performance and aesthetic standards.

How Does TDL Excel in Low-Pressure Injection Mold Manufacturing?

TDL excels in precision low-pressure injection mold manufacturing, transforming complex customer requests into high-quality molds using advanced techniques, rigorous quality control, and innovative solutions to overcome challenges.

How Does TDL Revolutionize Plastic Tester Mold Manufacturing?

TDL excels in plastic tester mold manufacturing by integrating innovation, precision, and expertise. They meet high industry standards and client demands through advanced techniques, rigorous quality control, and efficient solutions, ensuring excellence in every mold produced.

How Does TDL Achieve Precision in Knob Lock Mold Manufacturing?

TDL excels in manufacturing knob lock molds by leveraging advanced techniques, precision engineering, and rigorous quality control. Meeting stringent client requirements, they ensure high durability, efficient production cycles, and cost-effectiveness, showcasing their expertise in delivering exceptional mold solutions.

How Does TDL Lead the Way in Automotive Tank Mold Manufacturing?

TDL excels in automotive tank mold manufacturing by integrating precision, innovation, and advanced technology. Their expertise ensures high-quality, efficient, and durable molds that meet stringent industry standards and client requirements, overcoming challenges with strategic solutions and rigorous quality control.

How Does TDL Achieve Precision in Helical Gear Mold Manufacturing?

TDL excels in helical gear mold manufacturing by combining precision engineering, advanced technology, and rigorous quality control. Meeting stringent client demands, TDL delivers high-accuracy molds that ensure seamless gear transmission, addressing complex challenges with innovative solutions and maintaining industry-leading standards.

Some of our customers

Our Equipment

CMM

Inspection

High Speed CNC Machines

Double-Head EDM Machines

EDM

Workshop

CNC machining Workshop

Plastic Injection Molding Room

Mirror EDM Machining

Mould Spotting Machine

Plastic Injection Team

Meet Our Expert Team: The Driving Force Behind TDL Mold’s Innovative Solutions.

See how do we control the quality of injection molded parts

Related Topics

Choosing the Right Plastic for Injection Molding | Expert Insights

Typical Plastic Injection Molding Parameters Chart

Typical Plastic Injection Molding Parameters Chart as Shown Below (8 tables): 1-8 table: plastic LDPE HDPE Ethylene Propylene Copolymer PP PP Glass fiber reinforced PP PS HIPS ABS injection parameters 1, Injection molding machine type screws screws screws screws screws screws screws screws 2, screw type 1 […]

FAQ's

After years of working with thousands of injection molded parts, we’ve learned that many molding problems—like warping, short shots, or high tooling costs—can be traced back to design oversights that seemed minor at first. A well-optimized design minimizes tooling complexity, improves cycle time, and ensures dimensional accuracy. The most critical considerations include wall uniformity, draft geometry, material behavior, and mold flow optimization.

1. Maintain Consistent Wall Thickness

Consistent wall thickness helps maintain even cooling and prevents internal stress or distortion. When variation is unavoidable, transitions should be smooth and gradual. Thin sections cool faster but risk short shots; thicker sections cool unevenly and may cause sink marks. Designers typically keep wall thickness between 1–5 mm, adjusting by resin type and part size.

For example, we once helped a client redesign a consumer electronics housing that had visible sink marks around screw bosses. By adjusting wall transitions and adding ribs for support, we eliminated the surface defects and shortened cooling time by 15%.

2. Apply Proper Draft Angles

A proper draft angle allows easy part ejection and reduces wear on mold surfaces. Insufficient draft leads to sticking, scratches, or cracking during ejection.

The optimal draft depends on surface texture and part height—1°–2° for polished finishes and 3°–5° for textured molds. Applying draft in the ejection direction prevents drag and extends mold life.

We once optimized a medical device mold that originally had no draft — adding a 2° taper reduced ejection marks and extended tool life by more than 30%.

3. Choose Materials Based on Shrinkage and Use Conditions

Each plastic resin behaves differently during molding.

For instance, ABS offers great dimensional stability, while nylon (PA) absorbs moisture and shrinks more after cooling. We always recommend confirming material choice early, ideally with a mold flow analysis to predict shrinkage, flow balance, and potential air traps.

Ignoring this step often leads to dimensional mismatch between mating parts, especially in assemblies.

4. Use Ribs and Bosses Wisely

Thick walls don’t necessarily mean stronger parts — in fact, they often cause more defects. Reinforcing with ribs or gussets is a smarter approach. Keep ribs about 50–60% of wall thickness and always round corners to reduce stress.

For one automotive client, we added cross ribs under a large dashboard panel, improving stiffness while cutting part weight by 12%.

5. Optimize Gate and Cooling Design Together

The position of gates determines how the part fills, while cooling lines decide how it solidifies. These two systems must be designed together. A poorly placed gate can cause visible flow lines or trapped air, while inefficient cooling can increase cycle time by up to 20–30%.

During tooling, we often use conformal cooling channels on complex molds — it’s a higher upfront cost but can reduce long-term production time dramatically.

6. Control Tolerances Where It Matters

Not every feature needs tight tolerances. Over-specifying dimensions is a common cause of unnecessary tooling expense.

We advise applying critical-to-function (CTF) tolerances — focus precision only where parts assemble, seal, or align. For decorative surfaces, a slightly wider tolerance usually has no effect on fit or aesthetics.

7. Design for Maintenance and Longevity

Designers should avoid unnecessary undercuts or deep ribs that complicate tooling and increase mold wear.

A mold can run for years if designed with maintenance in mind. Avoid deep undercuts, fragile cores, or slides that require constant realignment. We’ve built production molds that have exceeded 500,000 cycles with minimal wear, simply because the design allowed for easy venting, lubrication, and component replacement.

Integrating DFM (Design for Manufacturability) and mold flow analysis early in development helps identify potential fill issues, venting needs, and ejection difficulties—reducing the number of tooling iterations.

Over the past 20 years, our team has produced injection molds for multiple industries, including automotive, consumer electronics, and medical components.

Based on our experience building hundreds of molds each year, we've found that tooling costs vary widely depending on part complexity, material selection, and expected production volume. A simple prototype mold for testing may cost only a few thousand dollars, while a multi-cavity production mold with precision steel tooling can easily exceed tens of thousands.

Typical Cost Ranges

1. Prototype and Low-Volume Molds (under 1,000 shots)

Usually made from aluminum or soft steel, these are used for design validation or early market testing.

Typical cost: $1,000–$5,000, with a lead time of about 2–4 weeks.

2. Mid-Volume Production Molds (1,000–50,000 shots)

Made from higher-grade aluminum or pre-hardened steel, suitable for small-batch production and product launches.

Typical cost: $5,000–$20,000, depending on part size and surface requirements.

3. High-Volume Production Molds (50,000–1,000,000+ shots)

Built from hardened steel such as P20 or H13, often with multiple cavities, hot runner systems, and precision cooling.

Typical cost: $20,000–$100,000 or more, with 4–8 weeks lead time.

For example, a recent 4-cavity automotive connector mold made from H13 steel costs around $35,000 and is rated for over 800,000 cycles before major maintenance.

Key Factors Affecting Tooling Cost

1. Part Design & Geometry

Deep ribs, sharp corners, or undercuts increase machining time and may require side actions or lifters. A simple open-shut mold can be 30–40% cheaper than a design with multiple slides.

2. Mold Material & Life Expectancy

Aluminum tools are quicker to produce but wear out faster. Steel molds cost more initially but last significantly longer—ideal for high-volume production or abrasive resins.

3. Cavity Count & Runner Type

Each additional cavity increases machining and fitting costs but reduces the cost per part.

Hot runner systems reduce material waste and cycle time but typically add 20–30% to initial tooling cost.

4. Manufacturing Location & Process Control

Offshore tooling (e.g., China) can save 30–50% on initial cost, but communication, tolerance control, and lead time should be considered. Many of our clients choose a hybrid approach—offshore tooling with in-house validation and maintenance.

Cost vs. Value

It’s important to view tooling as an investment, not just an expense. A well-built mold can run for years with consistent quality and minimal maintenance.

We’ve seen projects where investing 10–15% more in proper steel selection and cooling design reduced cycle time by 20%, paying back the difference within months.

Injection molding is a widely used manufacturing method for producing large volumes of plastic parts in materials ranging from thermoplastics to liquid silicone rubber.

While the core principle is simple, involving the injection of molten material into a mold to form a solid shape, the methods vary widely.

Over time, specialized molding techniques have evolved to meet different performance, design, and production needs across industries, from automotive to medical devices.

Standard injection molding

Standard injection molding is the foundation of modern plastic manufacturing. Most plastic parts you see or use every day, from appliance housings and automotive clips to electrical connectors and consumer electronics shells, are made using standard molding..

The method is straightforward yet highly refined: plastic pellets are melted, injected into a precision steel mold, cooled, and ejected as finished parts. It is built for volume — the repeatability makes it produce thousands or even millions of identical components with consistent dimensions and surface quality.

Typical parts include structural components, gear housings, and cosmetic shells made from materials such as ABS, PC, PP, and PA. Whether it’s a small precision connector or a large automotive fascia, standard injection molding remains the most reliable and cost-efficient solution for high-volume plastic manufacturing.

Overmolding & Insert Molding

Overmolding and insert molding are advanced variations of traditional injection molding, designed to combine multiple materials or components into a single, unified part. Both techniques enhance functionality, improve product durability, and eliminate the need for secondary assembly.

What is overmolding?

In overmolding, a base component, typically a rigid plastic, is first molded and then placed into another mold where a second, softer material is injected over it. This allows for the creation of parts with improved grip, comfort, or aesthetic contrast. You’ll see this method used in power tool handles, toothbrushes, and electronic housings with rubberized edges that provide protection and ergonomic feel.

What is insert molding?

Insert molding, on the other hand, integrates pre-formed parts such as metal inserts, threaded sleeves, or electronic contacts directly into the plastic during molding. The molten resin flows around the insert, locking it firmly in place and creating a strong mechanical bond. This process is ideal for producing components that require embedded strength or electrical conductivity, such as automotive connectors, sensor housings, or fastening points in consumer products.

Comparison: Overmolding vs. Insert Molding

Aspect | Overmolding | Insert Molding |

Purpose | Combines two or more plastics for added grip, comfort, or aesthetics | Integrates metal or composite inserts for strength, conductivity, or precision |

Material Combination | Plastic over plastic (rigid + soft) | Plastic over non-plastic (usually metal) |

Process Sequence | Base part is molded first, then overmolded with a second material | Insert is placed in the mold, and plastic is injected around it |

Typical Parts | Power tool handles, toothbrushes, phone cases, soft-touch grips | Automotive connectors, threaded inserts, sensor housings, fastening points |

Design Focus | Ergonomics, protection, and visual contrast | Structural strength, electrical function, and dimensional integrity |

Advantages | Enhances comfort and user experience | Reinforces mechanical and functional performance |

Cycle Efficiency | Two-shot or multi-stage process | Single injection cycle with embedded insert |

Both processes streamline production by combining materials and assembly in a single molding cycle. They deliver versatile solutions for modern product design.

Multi-shot (Two-Shot) Molding

Multi-shot, also known as two-shot molding, is an advanced molding process that allows two or more materials to be injected within a single molding cycle.

Instead of molding and assembling separate components, this process integrates multiple materials or colors directly in one machine, producing a fully finished part without secondary operations.

In practice, the first material forms the base structure — known as the substrate — while the second material is injected into a different cavity or through a rotating mold plate to bond with the first.

The two materials fuse together either chemically or mechanically, creating strong adhesion and precise alignment that cannot be achieved through conventional overmolding.

This process is ideal for applications that require both visual appeal and functional performance. For example, dual-color buttons, medical syringe handles, and consumer product dials often use this method to combine transparency, softness, or contrasting colors in a single part.

It also enhances production efficiency, reducing assembly costs and improving dimensional accuracy between different materials.

At TDL, we use multi-shot molding for projects that demand high precision and design flexibility. It’s particularly effective when a part requires different material properties in specific zones — such as a rigid body for structure and a soft surface for comfort or sealing.

Thin-Wall Injection Molding

Thin-wall injection molding is a specialized process developed for producing lightweight parts with very thin sections, typically less than 1 mm thick, without compromising strength or dimensional accuracy.

It’s driven by the growing demand for compact, high-performance products in industries like consumer electronics, medical devices, and packaging.

Unlike conventional molding, thin-wall production requires extremely fast injection speeds and higher pressures to fill the narrow cavities before the material begins to cool. Precision molds, high-flow resins, and efficient cooling systems are essential to ensure complete filling and prevent short shots or warpage. Even minor variations in flow or temperature can affect part quality, making tooling design and process control critical to success.

At TDL, we use advanced high-speed injection machines and optimized gating systems to achieve stable results in thin-wall molding. This process allows us to reduce material consumption and cycle time while maintaining the mechanical integrity and visual quality of each part.

Typical applications include smartphone housings, laptop shells, medical cartridge casings, and disposable food containers — all requiring strength, light weight, and clean aesthetics.

Thin-wall injection molding not only meets modern design trends for thinner, lighter products but also supports sustainable manufacturing by minimizing material use and energy consumption.

Rapid Injection Molding

Rapid injection molding is a streamlined approach to traditional molding, designed to shorten lead times and reduce tooling costs without sacrificing part quality.

Instead of using hardened steel molds, this process typically relies on aluminum or soft-steel tooling. This mold can be machined quickly and adapted easily for design changes. The goal is to bridge the gap between prototyping and full-scale production.

Engineers use rapid molding to produce functional parts made from production-grade materials for design validation, pilot runs, or market testing — all in a fraction of the time required for conventional tooling.

Typical applications include medical device prototypes, consumer product enclosures, and automotive components that need quick functional testing before mass production.

By combining DFM analysis, fast CNC machining, and flexible tool modification, rapid injection molding helps accelerate product development and reduce time to market.

Liquid Silicone Rubber (LSR) Molding

Liquid silicone rubber (LSR) molding is a specialized injection molding process designed for producing flexible, durable, and biocompatible components.

Unlike thermoplastic molding, where material solidifies through cooling, LSR molding involves injecting liquid silicone into a heated mold, where it cures chemically to form its final shape.

The process uses two liquid components — typically a base and a catalyst — that are mixed and metered into the injection unit in precise proportions. Because the material flows easily, it can fill thin or complex cavities with high accuracy, making it ideal for producing parts with fine details or soft-touch surfaces.

Common products include medical seals, baby pacifiers, keypads, and waterproof gaskets used in electronics. These parts maintain flexibility across a wide temperature range, resist chemicals and aging, and remain non-toxic — essential qualities for medical and consumer applications.

The process also supports multi-cavity molds and automated demolding, which enables high-volume production with consistent part quality.

Gas-Assisted Molding

Gas-assisted injection molding is an advanced variation of the traditional molding process used to produce large or thick-walled parts with improved strength, reduced weight, and better surface appearance.

The process begins similarly to standard injection molding, where molten plastic is injected into the mold. Before the cavity is completely filled, high-pressure nitrogen gas is introduced through precisely positioned channels.

The gas pushes the molten plastic against the mold walls, forming hollow sections within the part. This internal gas flow reduces material usage and eliminates surface defects such as sink marks or warping, which are common in thick or uneven parts.

For manufacturers, this method provides both structural and economic benefits. It shortens cooling times, minimizes residual stress, and often reduces the overall cycle time compared with solid plastic molding. The result is lighter, more stable components with clean surfaces and consistent dimensional accuracy.

Typical parts produced with gas-assisted molding include automotive handles, furniture frames, TV bezels, and appliance housings. These parts retain rigidity while cutting weight and material consumption — an advantage particularly valuable in automotive and consumer electronics industries.

Metal Injection Molding (MIM)

Metal injection molding (MIM) combines the precision of plastic injection molding with the strength and density of metal materials. It is used to produce small, intricate metal parts that would be difficult or expensive to make using conventional machining or casting methods.

The process begins with fine metal powder mixed with a polymer binder to form a feedstock that can be injected like plastic. After molding, the binder is carefully removed through a debinding process, and the remaining “green part” is sintered at high temperature to fuse the metal particles into a dense, solid structure. The result is a part with over 95% of the density and mechanical strength of wrought metal.

MIM is particularly effective for components requiring both complex geometry and high precision. Typical materials include stainless steel, titanium, and nickel alloys, making it suitable for applications where corrosion resistance, wear strength, or biocompatibility are essential.

Common parts produced with MIM include medical instruments, orthodontic brackets, watch components, firearm parts, and miniature gears used in consumer electronics.

The process enables tight tolerances, excellent surface finish, and mass production of parts that would otherwise require multiple machining steps.

Reaction Injection Molding (RIM)

Reaction injection molding (RIM) is a specialized process used to produce large, lightweight, and durable parts from thermosetting polymers.

Unlike traditional injection molding, which relies on melting solid resin pellets, RIM combines two liquid components—typically a polyol and an isocyanate—that chemically react inside the mold to form a solid polyurethane part.

Because the mixture has a very low viscosity, it flows easily into complex or thick-walled molds, allowing engineers to create parts that are both strong and lightweight.

The chemical reaction occurs at relatively low pressure and temperature, which means RIM molds can be made from aluminum instead of hardened steel, reducing tooling costs for large components.

This process is often chosen for parts where rigidity, impact resistance, and dimensional stability are essential. Typical products include automotive bumpers, dashboards, instrument housings, and enclosures for industrial equipment.

In some cases, the process is combined with fiberglass or other reinforcements (RRIM) to further enhance stiffness and structural integrity. RIM also supports textured finishes, in-mold painting, and insert placement, allowing large components to be produced with minimal post-processing.

Its ability to achieve high strength-to-weight ratios makes it a preferred choice in the automotive, aerospace, and heavy equipment industries.

Micro Injection Molding

Micro injection molding is a precision manufacturing process developed for producing extremely small and detailed plastic components — often weighing less than one gram — with tight dimensional tolerances.

It is commonly used in industries where miniaturization and reliability are critical, such as medical devices, electronics, and micro-mechanical systems.

The process follows the same principle as standard injection molding but uses specialized micro-scale machines and tooling capable of delivering highly controlled shot volumes. These machines feature fine screw or plunger systems that precisely meter molten resin into cavities often smaller than a few millimeters.

Because of the small size and intricate geometries involved, temperature and pressure control are vital to ensure material flow consistency and dimensional accuracy.

Typical materials include PEEK, LCP, POM, and medical-grade thermoplastics that offer excellent mechanical strength and chemical resistance.

Common parts made by micro injection molding include micro-gears, catheter tips, surgical instrument components, electronic connectors, and miniature optical housings.

This process offers unique advantages where traditional molding or machining would be impractical or uneconomical. It enables mass production of tiny, high-precision parts with repeatability and minimal waste, supporting innovations in next-generation medical, electronic, and sensor technologies.

By combining advanced molding control with ultra-fine tooling, micro injection molding pushes the boundaries of what is possible in precision plastic manufacturing.

Surface finish is one of the most overlooked yet influential aspects of injection molding. It doesn’t just determine how a part looks — it affects how it feels, performs, and even how efficiently it can be produced.

1. Visual Quality and Brand Perception

The surface finish defines the first impression of a product.

A high-gloss finish gives consumer products — such as phone housings or automotive interiors — a clean, premium look.

In contrast, matte or textured surfaces convey strength and practicality, often used for industrial or handheld tools.

Many brands intentionally use surface finish to align with their product identity: glossy for sophistication, textured for ruggedness.

Textures also help mask minor cosmetic flaws like flow lines, weld lines, or tool marks, creating a more uniform and professional appearance without additional finishing steps.

2. Functional Performance

Surface finish influences how a part behaves in real-world use.

For handheld products, a light texture improves grip and reduces slippage — critical for tools, sports equipment, and medical devices.

Smooth surfaces, on the other hand, reduce friction between moving parts and improve sealing performance, which is essential in valves, connectors, or gaskets.

A carefully selected finish can also enhance durability. For example, slightly roughened textures hide small scratches and resist abrasion better than mirror-polished surfaces, helping parts maintain their appearance over time.

3. Process and Manufacturing Efficiency

Surface finish choices also impact mold design and processing efficiency.

Highly polished cavities allow for easier part ejection and shorter cycle times but require more time and cost during mold fabrication.

Deep or complex textures may need additional draft angles to prevent sticking or part damage.

Engineers must balance these trade-offs during the design-for-manufacturing (DFM) stage to achieve consistent quality without unnecessary tooling expense.

At TDL, we often advise customers early in the design phase: A finely textured surface might save money in the long term by masking cosmetic defects and reducing post-processing requirements.

4. Material Compatibility

Not all plastics respond the same way to surface textures.

Amorphous materials like ABS or PC reproduce fine details and high gloss more easily, while fiber-reinforced resins may need a textured surface to hide fibers or prevent visible streaks.

Choosing the right pairing between material and mold finish ensures both consistent aesthetics and structural performance.

In practice, surface finish decisions should be made early — ideally during mold design. A well-matched finish not only defines how a product looks but also how it performs over time.

The right texture can hide flaws, reduce wear, or cut down on secondary finishing, turning what seems like a small design detail into a major factor in long-term product quality and cost.

Plastic injection molding is a manufacturing process used to produce a wide range of plastic parts and products. It is one of the most commonly used methods for mass-producing plastic components due to its efficiency, versatility, and cost-effectiveness. The process involves injecting molten plastic material into a mold cavity, allowing it to cool and solidify, resulting in the desired shape and form.

Here's an overview of the plastic injection molding process:

- Mold Making:The first step is to design and create a mold, which is a hollow cavity that defines the shape and dimensions of the final plastic part. The mold is usually made from steel or aluminum and consists of two halves: the "core" and the "cavity." These halves fit together precisely to form the complete mold.

- Clamping:The mold is mounted onto a specialized injection molding machine, which has a clamping unit responsible for holding the mold in place during the injection process.

- Injection:Plastic pellets or granules are fed into a heated barrel within the injection molding machine. The pellets are gradually heated and melted to form a viscous liquid (molten plastic). Once the required amount of plastic is melted, the injection process begins.

- Injection into the Mold:The molten plastic is injected into the mold cavity under high pressure through a nozzle. The pressure helps to fill the mold completely and evenly, replicating the mold's shape precisely.

- Cooling and Solidification:After the molten plastic is injected, the mold is allowed to cool, causing the plastic to solidify and take the shape of the mold cavity.

- Ejection:Once the plastic has cooled and solidified, the mold halves are separated, and the newly formed plastic part is ejected from the mold using ejection pins or mechanisms.

- Repeat Process:The entire cycle (clamping, injection, cooling, ejection) is repeated for the production of multiple parts. The process is highly automated, enabling the production of large quantities of identical parts efficiently and rapidly.

Plastic injection molding is widely used in various industries to manufacture a vast array of products, ranging from simple and small components to complex and large items, such as automotive parts, consumer electronics, medical devices, household items, and more. The ability to produce high-quality, consistent parts with tight tolerances makes plastic injection molding a preferred choice for many manufacturers.

The plastic injection molding process works through several distinct steps, each contributing to the efficient and precise production of plastic parts. Here's a detailed explanation of how the process works:

- Mold Manufacturing:The process begins with the creation of a mold, which is designed to match the desired shape of the plastic part. The mold is usually made from high-quality steel or aluminum and is created using computer-aided design (CAD) software and computer-aided manufacturing (CAM) techniques.

- Clamping:The mold is mounted onto the injection molding machine. The machine consists of a clamping unit, which holds the mold tightly closed during the injection and cooling processes. The clamping force is essential to ensure that the mold remains securely shut and the molten plastic does not leak.

- Injection:Plastic pellets or granules, typically in a hopper, are fed into a heated barrel of the injection molding machine. Inside the barrel, a screw-like plunger or reciprocating screw rotates and moves forward, melting the plastic due to the barrel's heat and pressure. The molten plastic accumulates at the front of the screw.

- Injection into the Mold:When the desired amount of molten plastic has accumulated, the injection phase begins. The forward movement of the screw or plunger forces the molten plastic through a nozzle and into the mold's cavity under high pressure. The mold's cavity is precisely shaped to match the final product design.

- Cooling and Solidification:Once the molten plastic fills the mold cavity, it is left to cool and solidify. Cooling is a critical stage, as it determines the final form and structure of the plastic part. The cooling time can vary depending on the material being used and the part's thickness.

- Ejection:After the plastic has sufficiently cooled and solidified, the mold opens using the clamping unit, and the newly formed plastic part is ejected from the mold. Ejection pins or air blasts help push the part out of the mold safely.

- Repeat Process:The entire cycle (clamping, injection, cooling, ejection) is then repeated for the production of the next plastic part. The process is highly automated, and modern injection molding machines can repeat this cycle hundreds or even thousands of times per hour.

It's worth noting that injection molding machines are equipped with sophisticated controls and sensors to monitor and adjust various parameters, such as temperature, pressure, and cooling time, ensuring the production of consistent, high-quality parts. The versatility and efficiency of the plastic injection molding process have made it an integral part of various industries, ranging from automotive and electronics to healthcare and consumer goods.

Plastic injection molding is a versatile manufacturing process that can produce a wide range of products, both simple and complex. Here are some common types of products that can be made using plastic injection molding:

- Consumer Electronics:

Plastic injection molding is widely used to produce various components of consumer electronic devices, such as phone cases, laptop housings, keyboard keys, camera parts, and charger connectors.

- Automotive Parts:

Many interior and exterior automotive components are made through injection molding, including dashboard panels, door handles, bumpers, interior trims, and ventilation system parts.

- Medical Devices:

Plastic injection molding is crucial in the medical industry for manufacturing items like syringes, medical tubing, connectors, instrument casings, and disposable medical supplies.

- Packaging Products:

Plastic injection molding is commonly used for producing a variety of packaging products like caps, closures, bottles, containers, and food packaging.

- Household Items:

Numerous everyday household items are manufactured using injection molding, including kitchen utensils, toys, storage bins, hangers, and garden tools.

- Appliance Components:

Plastic injection molding is used to create parts for appliances such as washing machine drums, refrigerator components, and vacuum cleaner casings.

- Industrial Components:

Many industrial products, such as gears, valves, electrical switches, and connectors, are made through injection molding due to its ability to produce high volumes with precision.

- Personal Care Products:

Items like toothbrushes, razors, cosmetic containers, and shampoo bottles are commonly produced using plastic injection molding.

- Construction Materials:

Certain construction materials like PVC pipes and fittings are manufactured through injection molding.

- Sports Equipment:

Various sports equipment parts, such as bicycle components, ski bindings, and protective gear, are made using plastic injection molding.

- Office Supplies:

Office products like pen casings, stapler components, and printer parts are often produced through this process.

- Toys and Games:

Many plastic toys and game pieces are manufactured using injection molding due to its ability to produce intricate shapes and details.

The versatility, efficiency, and cost-effectiveness of plastic injection molding make it a preferred choice for a wide range of industries. It allows for the mass production of high-quality, consistent plastic parts with intricate designs and precise dimensions, meeting the demands of modern manufacturing and consumer markets.

Plastic injection molding supports a variety of materials, each with its unique properties and characteristics. The choice of material depends on the specific requirements of the product being manufactured, such as strength, flexibility, heat resistance, chemical resistance, transparency, and more. Some common materials used in plastic injection molding include:

- Polyethylene (PE):

Polyethylene is a versatile and widely used thermoplastic with excellent chemical resistance, electrical properties, and low moisture absorption. It comes in various forms, including high-density polyethylene (HDPE) and low-density polyethylene (LDPE).

- Polypropylene (PP):

Polypropylene is another versatile thermoplastic with good mechanical properties, chemical resistance, and high heat resistance. It is commonly used for products like packaging containers, automotive parts, and household items.

- Polyvinyl Chloride (PVC):

PVC is a durable thermoplastic known for its excellent weather resistance, making it suitable for outdoor applications like pipes, fittings, and vinyl siding.

- Acrylonitrile Butadiene Styrene (ABS):

ABS is a tough and impact-resistant thermoplastic commonly used in automotive parts, electronic enclosures, and toys.

- Polycarbonate (PC):

Polycarbonate is a transparent thermoplastic with high impact resistance, making it suitable for products like safety glasses, CDs, and electronic components.

- Polyethylene Terephthalate (PET):

PET is a strong and lightweight thermoplastic commonly used for beverage bottles, food containers, and synthetic fibers.

- Polyurethane (PU):

Polyurethane is a versatile material known for its flexibility and durability. It is used in applications such as foam seating, automotive parts, and shoe soles

- Nylon (Polyamide):

Nylon is a strong and abrasion-resistant thermoplastic often used in applications requiring high mechanical strength, such as gears and bearings.

- Polystyrene (PS):

Polystyrene is a rigid and transparent thermoplastic used in items like food packaging, disposable cutlery, and CD cases.

- Polyoxymethylene (POM) / Acetal:

POM is a highly crystalline and durable thermoplastic used in applications like gears, bearings, and automotive components.

- Polyphenylene Sulfide (PPS):

PPS is a high-performance thermoplastic known for its chemical resistance and high-temperature capabilities, suitable for automotive and electronic components.

- Polyether Ether Ketone (PEEK):

PEEK is an advanced engineering thermoplastic with excellent mechanical and thermal properties, used in aerospace, medical, and industrial applications.

These are just a few examples of the materials commonly used in plastic injection molding. There are many other specialty and engineering-grade plastics available, each tailored to specific applications and performance requirements. The selection of the appropriate material is crucial in ensuring that the final product meets its intended functionality and performance standards.

Plastic injection molding offers numerous advantages, making it one of the most widely used and preferred manufacturing processes for plastic parts and products. Here are some of the key advantages of plastic injection molding:

- High Efficiency and Production Speed:Plastic injection molding is a highly efficient process, capable of producing large quantities of identical parts quickly and consistently. The automated nature of the process allows for rapid cycle times, reducing production lead times.

- Cost-Effective for Mass Production:Once the initial mold is created, the cost per unit decreases significantly for larger production runs. This makes plastic injection molding a cost-effective solution for high-volume production, helping to lower overall manufacturing costs.

- Versatility in Design:The process allows for intricate and complex part designs to be created with precision. It can accommodate a wide range of part sizes and shapes, giving designers the flexibility to bring innovative and creative ideas to life.

- Consistent and High-Quality Parts:Injection molding produces parts with high dimensional accuracy and repeatability. The use of precise molds and automated controls ensures that each part is consistently manufactured to the same exact specifications.

- Wide Selection of Materials:Plastic injection molding supports a vast array of materials, including commodity plastics, engineering-grade plastics, and specialty plastics, each with unique properties to suit specific application requirements.

- Minimal Material Waste:The process is designed to minimize material waste, as any excess plastic can often be reused for future production runs. This helps reduce material costs and makes it an environmentally-friendly manufacturing option.

- Reduced Post-Production Finishing:Many parts produced through injection molding require little to no additional finishing, as the molds can produce finished surfaces with smooth textures and accurate details.

- Automation and Labor Savings:Injection molding machines are highly automated, requiring minimal human intervention during the production process. This automation helps reduce labor costs and increases overall production efficiency.

- Design for Manufacturability (DFM):Injection molding encourages design simplicity and allows for the integration of multiple features into a single part, which can streamline assembly processes and reduce the number of components needed.

- Scalability and Adaptability:The process is easily scalable, accommodating both low-volume and high-volume production needs. It also allows for quick adjustments in design or material changes when required.

- Wide Range of Applications:Plastic injection molding is used in various industries, such as automotive, electronics, medical, consumer goods, aerospace, and more, highlighting its versatility and applicability.

Overall, plastic injection molding offers manufacturers a reliable and efficient method to produce high-quality plastic parts and products, contributing to cost-effectiveness, design freedom, and the ability to meet demanding production requirements.

While plastic injection molding offers numerous advantages, it also has some disadvantages that manufacturers should consider when deciding on the most suitable production method. Here are some of the key disadvantages of plastic injection molding:

- High Initial Tooling Cost:Creating the mold (tooling) for injection molding can be expensive, especially for complex designs or large parts. The cost of mold fabrication and setup can make the process less viable for small production runs or prototypes.

- Lead Time for Tooling:Designing and manufacturing molds can take several weeks or even months, leading to longer lead times before the production process can begin. This can be a disadvantage for projects with tight timelines.

- Limited Material Selection for Some Designs:While plastic injection molding supports a wide range of materials, specific design requirements (e.g., extreme temperature resistance, chemical compatibility) may necessitate the use of specialized and more expensive materials.

- Part Design Limitations:Certain part designs may be challenging or even impossible to mold using conventional injection molding techniques. Sharp corners, thin walls, or complex undercuts can complicate the process or result in defects.

- High Part Cost for Low-Volume Production:For small production runs, the cost of tooling and setup may make each part prohibitively expensive, making other manufacturing methods more cost-effective for low-volume production.

- Material Waste and Environmental Concerns:Although efforts are made to minimize material waste, some scrap plastic is generated during the production process. This can be a concern for environmental sustainability, especially if the material is not easily recyclable.

- Design Changes Require New Tooling:If design modifications are necessary after the mold has been created, new tooling may be required, adding significant costs and lead time.

- Cycle Time Limitations:The cooling time during the injection molding process is a crucial factor that can affect cycle times. Thick parts or materials with slow cooling rates may result in longer cycle times, impacting production speed.

- Risk of Defects:Injection molding is a precise process, and any variations in material, temperature, or pressure can lead to defects in the final product, requiring additional quality control measures.

- Energy Consumption:Injection molding machines can consume a significant amount of energy, which may result in higher production costs and environmental impact.

Despite these disadvantages, plastic injection molding remains a highly popular and practical manufacturing method for a wide range of applications. Manufacturers should carefully consider their specific project requirements and weigh the advantages and disadvantages of injection molding against other available processes to make informed decisions.

Reducing the cost of plastic injection molding requires careful consideration of various factors throughout the manufacturing process. Here are some strategies to help you lower the overall cost of injection molding:

- Optimize Part Design:

Work closely with experienced designers and engineers to optimize the part design for injection molding. Simplifying the design, reducing unnecessary features, and minimizing wall thickness can help lower material usage and reduce production time.

- Consolidate Parts:

Where possible, consolidate multiple parts into a single component. This reduces the number of molds needed and streamlines the assembly process, resulting in cost savings.

- Choose the Right Material:

Selecting an appropriate material that meets the required performance and appearance standards can prevent the need for costly material changes or secondary operations.

- Avoid Undercuts and Complex Features:

Undercuts and complex features in the part design can increase tooling and production costs. Design the part with features that can be easily ejected from the mold without the need for additional mechanisms.

- Use Standard Mold Bases:

Utilize standard mold bases and components whenever possible, as custom tooling can significantly increase the cost.

- Reduce Mold Complexity:

Minimize the number of cavities in the mold if high production volumes are not required. A simpler mold design can reduce tooling costs.

- Consider Aluminum Molds:

For smaller production runs or prototypes, aluminum molds can be a more cost-effective alternative to steel molds. Although they have a shorter lifespan, they can be manufactured more quickly and at a lower cost.

- Implement Automation:

Automating certain aspects of the production process can reduce labor costs and improve production efficiency.

- Optimize Cooling and Cycle Time:

Efficient cooling channels in the mold can shorten cycle times, increasing production output and reducing energy costs.

- Negotiate with Suppliers:

Work closely with suppliers and manufacturers to negotiate favorable terms, especially when it comes to material costs and production volume discounts.

- Consider Local Manufacturing:

Manufacturing products closer to the end-users can reduce shipping costs and lead times, making local production a cost-effective option.

- Perform Cost Analysis:

Regularly analyze the cost of each part and the overall production process. Identify areas where cost-saving measures can be implemented.

- Continuous Improvement:

Implement a culture of continuous improvement to identify and address inefficiencies and cost drivers in the manufacturing process.

The quality of a plastic injection molded part is influenced by a combination of factors throughout the entire manufacturing process. These factors can affect the part's dimensional accuracy, surface finish, strength, and overall consistency. Here are some key factors that impact the quality of a plastic injection molded part:

- Part Design:The initial part design plays a crucial role in determining the final part's quality. Properly designed parts with appropriate wall thickness, uniform sections, and well-rounded corners facilitate smooth material flow during injection and help prevent defects.

- Material Selection:The choice of plastic material can significantly impact the part's mechanical properties, chemical resistance, and appearance. The material must be selected based on the part's specific requirements and the intended application.

- Mold Design and Construction:The mold design is essential for producing high-quality parts. Factors such as gate placement, cooling channel design, and venting influence the material flow, cooling rate, and release of air or gas from the mold cavity.

- Injection Molding Machine Settings:Properly calibrating the injection molding machine is critical to achieving consistent and repeatable results. Factors such as injection speed, temperature, pressure, and holding time must be optimized based on the material and part design.

- Injection Molding Process Conditions:Maintaining consistent process conditions, such as melt temperature, mold temperature, and injection pressure, helps ensure consistent part quality throughout the production run.

- Cooling and Solidification:Proper cooling of the molded part is essential to prevent warping and ensure dimensional stability. Balanced cooling channels in the mold help achieve uniform cooling and reduce cycle times.

- Mold Maintenance:Regular maintenance and cleaning of the mold are essential to prevent buildup of contaminants or residue that could affect part quality and lead to defects.

- Post-Molding Operations:Any secondary operations, such as trimming, drilling, or assembly, should be carefully performed to avoid damage or deformation of the part.

- Quality Control and Inspection:Implementing a comprehensive quality control process is essential to detect and address any defects or variations in the parts. Inspection techniques such as dimensional measurements, visual inspection, and material testing are commonly used.

- Operator Skill and Training:The expertise of the machine operators and technicians can significantly impact the quality of the molded parts. Proper training and skill development are essential to ensure consistent production and troubleshooting capabilities.

- Environmental Conditions:Factors such as temperature and humidity can affect the material properties and the injection molding process. Controlling the environment can help maintain consistent results.

Addressing these factors and maintaining strict quality control procedures throughout the entire injection molding process will help ensure the production of high-quality plastic parts that meet the desired specifications and performance standards.

By employing these cost-saving strategies, you can make plastic injection molding a more cost-effective and efficient manufacturing method for your products. It's essential to strike a balance between cost reduction and maintaining the required quality and functionality of the final product. Work closely with experienced manufacturers and engineers to ensure the best results.

Plastic injection molding and blow molding are two distinct manufacturing processes used to produce plastic parts and products, each with its unique characteristics and applications. The main difference between the two processes lies in how the plastic material is shaped and formed. Here's an overview of each process:

- Plastic Injection Molding:

In plastic injection molding, the process involves injecting molten plastic material into a closed mold cavity to create the desired shape of the part. The mold is typically made of steel or aluminum and consists of two halves: the "core" and the "cavity." The molten plastic is injected into the mold at high pressure, filling the cavity and taking on its shape. Once the plastic cools and solidifies, the mold opens, and the finished part is ejected.

Key characteristics of plastic injection molding:

- Suitable for producing complex and detailed parts with tight tolerances.

- Ideal for high-volume production runs due to its efficiency and repeatability.

- Can handle a wide range of plastic materials, including engineering-grade and high-performance plastics.

- Commonly used for producing a variety of products, such as automotive components, consumer electronics, medical devices, and household items.

- Blow Molding:

Blow molding is a process used to create hollow plastic parts, such as bottles, containers, and tanks. It involves a two-step process: extrusion and blowing. In the extrusion step, a tube-like plastic parison (a hollow tube of molten plastic) is created by extruding it through a die. The parison is then placed inside a mold, and air is blown into the parison, expanding it to the shape of the mold cavity. The plastic material conforms to the mold's shape and solidifies to create the final part.

Key characteristics of blow molding:

- Primarily used for producing hollow parts with thin walls, such as bottles and containers.

- Suitable for large-scale production of identical parts with minimal material waste.

- Limited to producing hollow shapes, making it less versatile for complex parts compared to injection molding.

- Commonly used in industries such as packaging, beverage, and automotive for items like bottles, containers, and automotive ducts.

In summary, plastic injection molding is best suited for producing solid, complex, and detailed parts with high accuracy and repeatability, making it ideal for a wide range of applications. On the other hand, blow molding is specialized for creating hollow, thin-walled parts, particularly containers and bottles, in large quantities. Each process has its advantages and limitations, and the choice between the two depends on the specific requirements of the product being manufactured.

Insert molding is a specialized plastic injection molding process that involves inserting a pre-formed component (the "insert") into the mold before injecting molten plastic around it to form a single integrated part. This technique allows plastic and other materials, such as metal or another plastic component, to be combined into a finished product in one molding operation. Insert molding offers several advantages, including improved part strength, reduced assembly steps, and increased design flexibility.

Here's a step-by-step overview of the insert molding process:

- Insert Placement:First, the pre-formed insert is placed into the mold cavity or onto a core pin. The insert can be made of various materials, such as metal screws, pins, electrical contacts, or other plastic components.

- Mold Clamping:The mold, which consists of two halves (core and cavity), is closed and clamped tightly to secure the insert in the desired position.

- Injection:Molten plastic material is injected into the mold under high pressure. The plastic flows around and over the insert, encapsulating it completely.

- Cooling and Solidification:The molten plastic cools and solidifies around the insert, fusing the insert and the plastic material into a single, cohesive part.

- Mold Opening and Ejection: Once the plastic has solidified, the mold is opened, and the completed insert-molded part is ejected from the mold.

Insert molding offers several benefits:

- Enhanced Part Strength:The insert provides additional structural support, improving the part's strength and rigidity compared to conventional overmolding or assembly methods.

- Streamlined Assembly:By combining multiple components into a single molded part, insert molding reduces the need for separate assembly steps, saving time and labor costs.

- Design Flexibility:Insert molding allows for creative and compact designs, enabling engineers to integrate various functionalities into a single part.

- Cost Savings:Despite the initial setup for insert placement, insert molding can lead to cost savings in the long run due to simplified assembly processes and reduced material waste.

Insert molding is widely used in various industries, including automotive, electronics, medical devices, and consumer goods. Common applications include adding metal contacts to electrical connectors, incorporating threaded inserts for fastening purposes, and integrating reinforcing elements into plastic parts for improved structural integrity. The ability to combine different materials and functionalities within a single molded part makes insert molding a valuable technique for enhancing the performance and functionality of plastic components.