Choosing the right injection molding company in China isn’t as simple as searching “top suppliers” and picking the cheapest quote. We’ve seen it happen too many times—someone picks an injection molding supplier in China based only on price, and ends up with missed deadlines, poor tolerances, or worse.

That’s why we put together this shortlist of top injection molding companies in China. They’re manufacturers with proven capabilities, export experience, and a track record of getting things right.

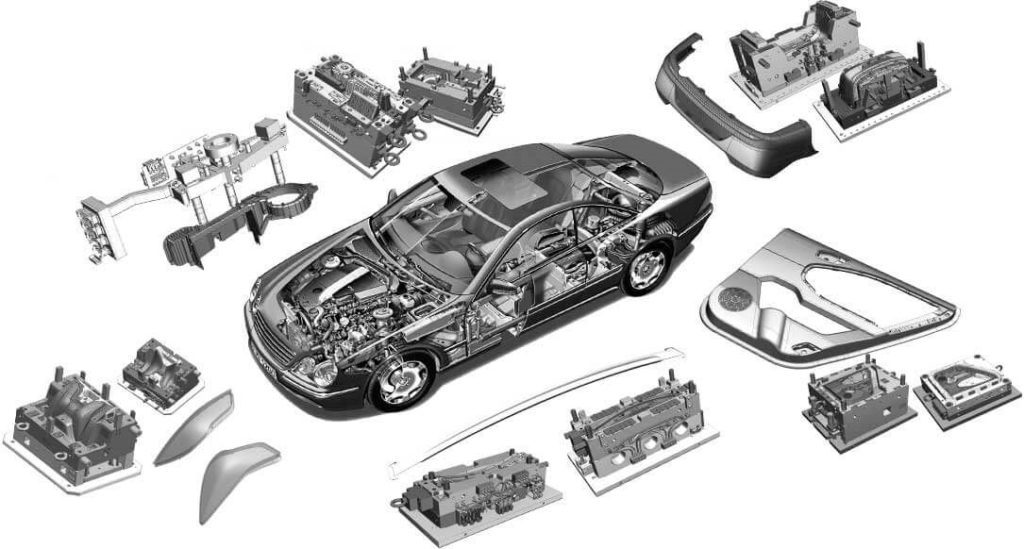

Whether you’re building automotive components, consumer product housings, or tight-tolerance prototypes, these are suppliers worth your shortlist.

Quick Comparison: Top Injection Molding Companies in China

If you don’t have time to read through every profile just yet, here’s a quick side-by-side look at the top ten injection molding companies in China. This table covers the essentials, so you can quickly spot who’s best suited for your project based on experience, capabilities, certifications, and core industries.

| Rank | Company Name | Founded | Core Industries | Certifications | Key Capabilities | Location |

| 1 | TDLmould | 1995 | Automotive, Medical, Consumer Goods | ISO 9001 | Mold design, Tooling, Injection molding, Post-processing | Dongguan, Guangdong |

| 2 | DJmolding | 2010 | Electronics, Appliances, OEM | ISO 9001:2015 | Rapid prototyping, Injection molding, Painting, Assembly | Shenzhen, Guangdong |

| 3 | HLH Prototypes | 2008 | Prototyping, Medical, Consumer Products | ISO 9001 | Mold making, CNC machining, 3D printing, Sheet metal | Shenzhen, Guangdong |

| 4 | 3ERP | 2008 | Automotive, Electronics, Industrial | ISO 9001:2015 | Injection molding, Rapid tooling, CNC, DfM support | Zhongshan, Guangdong |

| 5 | Eco Molding | 2008 | Electronics, Appliances | ISO 9001:2008 | Mold design, CNC, Low-volume injection molding | Shenzhen, Guangdong |

| 6 | Focare Mould | 2012 | Personal Care, Packaging, Medical | — | Double-color molds, Injection molding, After-sales support | Taizhou, Zhejiang |

| 7 | HanKing Mould | 1996 | Automotive, Medical, Home Appliance | ISO 9001, ISO 14001, IATF 16949 | Full-process solution, High-precision molding | Dongguan, Guangdong |

| 8 | RJC Mold | 2002 | Automotive, Electronics, Industrial | ISO 9001:2015, IATF 16949 | Injection molding, Mold making, Assembly, CNC | Shenzhen, Guangdong |

| 9 | FOW Mould | 1978 | Automotive, Household, Industrial | ISO 9001 | Mass production, Rapid prototyping, Mold making | Taizhou, Zhejiang |

| 10 | Zetar Industry | 2005 | Electronics, Automotive, Consumer Goods | ISO 9001 | Mold design, Injection molding, Overmolding, Insert molding | Shanghai |

Need a partner for a tight-tolerance mold? TDL Mould or HanKing Mould might be your best bet. Working in automotive? RJC Mold and JMT both specialize in that space. The profiles below will help you dive deeper into what each company offers—and why they made the list.

1. TDLMould Company

Capabilities:

- In-house mold design, mold making, injection molding, and post-processing

- Equipment range: 90–650 tons (MAKINO, FANUC, YIZUMI systems)

- Services include ultrasonic welding, silk/pad printing, electroplating, painting, and full assembly

- ISO 9001 certified quality management

- Serves the automotive, medical, and consumer electronics industries

Website: www.tdlmould.com

Founded: 1995

Location: Dongguan, Guangdong, China

Email: jason@tdlmould.com

Phone: +86-0769-8228 8296

What makes TDLmould worth considering is their vertical integration—they handle mold design, fabrication, injection molding, and assembly all in-house. That means fewer delays and tighter control. They’re not the cheapest, but they’re dependable. If your project involves custom molds, moderate production volumes, and needs extra steps like plating or pad printing, this supplier can deliver without micromanaging.

2. DJmolding

Capabilities:

- Custom mold making and plastic injection molding services

- Supports small to medium production runs and rapid prototyping

- Works with ABS, PC, PP, POM, PA6, TPU, and other engineering-grade plastics

- Offers secondary processes including painting, ultrasonic welding, and light assembly

- ISO 9001:2015 certified; exports to Europe, North America, and Southeast Asia

Website: www.djmolding.com

Founded: 2010

Location: Shenzhen, Guangdong, China

Email: info@djmolding.com

Phone: +86-18169936698

DJmolding is best suited for small and mid-size businesses looking for flexible injection molding services with export experience. The company offers one-stop production from tooling to part delivery, and is known for its responsive service, stable quality, and willingness to handle low-volume or complex jobs that many larger factories avoid.

3. HLH Prototypes Co., Ltd.

Capabilities:

- Custom injection mold making and plastic part production

- Supports rapid prototyping and low-to-medium volume manufacturing

- Also offers CNC machining, 3D printing, vacuum casting, and sheet metal fabrication

- Works with ABS, PC, PA, POM, PMMA, and more

- ISO 9001 certified; experienced with global export compliance

Website: www.hlhrapid.com

Founded: 2008

Location: Shenzhen, Guangdong, China

Email: info@hlhrapid.com

Phone: +44 113 824 3578

HLH is ideal if you’re developing a new product and need both prototype molds and small-to-mid volume injection molding. With strong in-house capabilities and global client experience, they’re a practical choice for startups and engineering teams needing flexibility, speed, and multi-process support beyond just molding.

4. 3E Rapid Prototyping (3ERP)

Capabilities:

- Plastic injection molding and rapid tooling for low to medium volume production

- In-house CNC machining, die casting, and vacuum casting

- Mold manufacturing with fast turnaround and full DfM support

- Works with engineering plastics: ABS, PC, POM, PA, PMMA, etc.

- ISO 9001:2015 certified, strong track record with US/EU clients

Website: www.3erp.com

Founded: 2008

Location: Zhongshan, Guangdong, China

Email: projects@3erp.com

Phone: +86 760 8841 1100

3ERP is a solid pick for companies needing fast, flexible injection molding services with export-grade quality. Their integrated prototyping and production capabilities make them a go-to choice for engineers, startups, and product developers looking to accelerate time-to-market while staying in control of quality and cost.

5. Eco Molding Co., Ltd.

Capabilities:

- Custom plastic injection molding for small to medium batch sizes

- In-house mold design, CNC machining, and mold manufacturing

- Injection molding machines ranging from 80 to 450 tons

- Production of parts up to 1,500g; monthly output of 40–50 molds

- Expertise in automotive, electronics, home appliances, and industrial OEM applications

- ISO 9001:2008 certified

Website: www.ecomolding.com

Founded: 2008

Location: Songgang Town, Shenzhen, Guangdong, China

Email: sales@injectionmold.cn

Phone: 0086-(0)755 3318 3226

Eco Molding Co., Ltd. is a reliable partner for businesses seeking high-quality plastic injection molding services in China. With a focus on precision and efficiency, they offer comprehensive solutions from mold design to final product assembly. Their commitment to quality is evidenced by their ISO 9001:2008 certification and a dedicated team of over 100 professionals. Eco Molding’s modern facility and advanced equipment ensure timely delivery and consistent product quality, making them a preferred choice for clients worldwide.

6. Focare Mould Co., Ltd.

Capabilities:

- Specializes in double-color (2K) and multi-material injection mold making

- Provides custom mold design, mold fabrication, and injection molding services

- Experienced in products for personal care, household goods, and medical packaging

- Offers mold testing, product development assistance, and after-sales support

- Serves global clients in Latin America, Europe, and Southeast Asia

Website: www.focaremould.com

Founded: 2012

Location: Taizhou, Zhejiang, China

Email: sale@focaremould.com

Phone: +886-932876644

Focare Mould is a go-to choice for companies seeking high-quality double-color or multi-component plastic parts. Their expertise in tooling for personal care and consumer products, combined with deep mold design know-how, makes them ideal for international buyers needing stable production, fast iteration, and full support from DFM to mold trials.

7. HanKing Mould Engineering Ltd.

Capabilities:

- One-stop solutions including mold design, mold making, injection molding, secondary processing, and product assembly

- Specializes in precision plastic injection molds for automotive, electronics, medical, and home appliance industries

- Operates 145+ injection molding machines ranging from 90 to 1000 tons

- Extensive export experience with clients across the US, Germany, Switzerland, France, Italy, Austria, and Israel

- Certified with ISO 9001, ISO 14001, and IATF 16949 for quality management and environmental standards

Website: www.hanking-mould.com

Founded: 1996

Location: No. 23 Xingye Road, Chang’an Town, Dongguan City, Guangdong Province, China

Email: yoyo@hanking-mould.com

Phone: +86-137-9825-7041

HanKing Mould stands out for its full-spectrum capabilities—from concept to finished product. Their expertise in precision molding is backed by decades of experience and a proven international client base. If your project demands tight tolerances, export-grade quality, and smooth communication across the production lifecycle, HanKing is a strong candidate to consider.

8. RJC Mold

Capabilities:

- Custom plastic injection molding for low to high-volume production

- In-house mold design, CNC machining, and mold manufacturing

- Injection molding machines ranging from 80 to 650 tons

- Production of parts up to 1,500g; monthly output of 40–50 molds

- Expertise in automotive, electronics, home appliances, and industrial OEM applications

- ISO 9001:2015 and IATF 16949 certified

Website: www.rjcmold.com

Founded: 2002

Location: Shenzhen, Guangdong, China

Email: info@rjcmold.com

Phone: +86-755-27284387

RJC Mold is a reliable partner for businesses seeking high-quality plastic injection molding services in China. With a focus on precision and efficiency, they offer comprehensive solutions from mold design to final product assembly. Their commitment to quality is evidenced by their ISO 9001:2015 and IATF 16949 certifications and a dedicated team of over 100 professionals. RJC Mold’s modern facility and advanced equipment ensure timely delivery and consistent product quality, making them a preferred choice for clients worldwide.

9. FOW Mould

Capabilities:

- Custom plastic injection molding and mold making

- Expertise in automotive, household, and industrial products

- In-house design, CNC machining, and rapid prototyping

- ISO 9001 certified; supports high-volume production

Website: www.immould.com

Founded: 1978

Location: Huangyan, Taizhou, Zhejiang, China

Email: info@immould.com

Phone: +86-576-8402 3885

FOW Mould is a seasoned manufacturer specializing in plastic injection molding and mold making. With over four decades of experience, they offer comprehensive services from product design to mass production. Their commitment to quality and efficiency makes them a preferred partner for clients worldwide.

10. Zetar Industry Co., Limited

Capabilities:

- Custom plastic injection molding and mold design

- Specializes in electronics, automotive, and consumer products

- Offers prototyping, overmolding, and insert molding

- ISO 9001 certified; caters to both low and high-volume production

Website: www.zetarmold.com

Founded: 2005

Location: Shanghai, China

Email: sales@zetarmold.com

Phone: +86-21-5950 2060

Zetar Industry Co., Limited is a Shanghai-based company offering comprehensive plastic injection molding services. Their expertise spans various industries, providing clients with tailored solutions from concept to final product. Their emphasis on quality and customer satisfaction has earned them a solid reputation in the global market.

How to Choose the Right Partner Based on Your Industry

Not all injection molding suppliers are built the same. Your industry-specific requirements—whether it’s regulatory compliance, precision, or speed—should guide who you work with. Below are tailored recommendations to help you find the right partner based on your sector.

Automotive Projects

When it comes to automotive parts, you can’t afford dimensional drift or poor repeatability. You’ll need a partner familiar with:

- IATF 16949 certification

- High-volume tooling durability

- Complex geometries and undercuts

- Materials like PA6+GF, POM, or PC-ABS blends

Recommended Partners:

- JMT Automotive Mold: Decades of mold experience and strong 5-axis CNC capabilities make it ideal for large, precision automotive tools.

- RJC Mold: IATF 16949 certified and experienced in delivering production-ready parts to global Tier 1 and OEMs.

Consumer Electronics

For consumer electronics, aesthetics, precision, and turnaround speed matter just as much as structural performance. Common requirements include:

- Tight cosmetic tolerances

- High-gloss or textured surface finishes

- Compatibility with insert molding and overmolding (e.g., for housings, grips, buttons)

- Rapid prototyping support for fast design validation

Recommended Partners:

- TDLmould: Their vertically integrated setup and full-service capabilities (mold design to printing and assembly) are ideal for streamlined development of electronics enclosures and components.

- Eco Molding: Offers strong support for short runs and quick mold cycles, which is well-suited for iterative consumer product development.

Medical & Industrial Applications

Medical and industrial projects require more than just good molds—they demand process control, material traceability, and compliance with strict quality standards. For these sectors, consider:

- Certifications like ISO 13485, IATF 16949, or ISO 9001

- High precision and consistency across batches

- Support for engineering-grade or biocompatible plastics

- Long tool life and cleanroom-ready production, where applicable

Recommended Partners:

- HanKing Mould: With IATF 16949 and ISO 14001 certifications, plus deep experience in high-precision applications, they’re a reliable choice for both medical devices and complex industrial assemblies.

- Focare Mould: Well-suited for medical packaging and consumer health products, especially where multi-material or 2K molding is involved. Their mold design expertise makes them a practical choice for high-consistency applications.

How to Evaluate Injection Molding Suppliers in China

Choosing the right injection molding partner goes beyond checking their equipment list or website. You need a supplier that aligns with your technical needs, quality expectations, and communication style. Here are the key criteria to evaluate before committing:

1. Manufacturing Capabilities

Start by matching the supplier’s machine size, material expertise, and mold-making capacity with your product specs.

- Do they support your part’s tonnage and material type (e.g., ABS, PC, POM)?

- Can they handle complex processes like overmolding, insert molding, or multi-shot molding?

- Do they manage tooling in-house or outsource it?

Why it matters: A mismatch here leads to poor tolerances, high scrap rates, or longer lead times.

2. Quality Management & Certifications

Look for suppliers with robust quality systems and relevant certifications:

- ISO 9001 – Basic quality management for all industries

- IATF 16949 – Required for automotive projects

- ISO 13485 – For medical devices

- RoHS/REACH compliance – For electronics or export-sensitive industries

Also, check if they offer:

- Incoming material inspection

- First Article Inspection (FAI)

- Statistical Process Control (SPC)

Why it matters: Strong quality processes reduce rework and ensure consistency, especially for long-term or regulated projects.

3. DFM Support and Engineering Know-How

A supplier’s ability to offer Design for Manufacturability (DFM) feedback early can make or break your launch schedule.

- Do they review your CAD files before mold making?

- Will they flag design flaws or risk areas like undercuts and wall thickness variations?

- Can they optimize gate location, cooling channels, or ejector pin layout?

Why it matters: Experienced suppliers help you avoid costly mold changes and delays later in the process.

4. Lead Time and Scalability

Understand their typical tooling and production timelines:

- How long do they take for tool fabrication and T1 samples?

- What’s their standard cycle time for production orders?

- Can they scale up from 500 units to 50,000 if needed?

Why it matters: If your project grows, you’ll want a partner who can keep up without quality trade-offs.

5. Communication and Project Management

Don’t overlook soft skills. Look for:

- Fluent English communication

- Transparent quoting and timeline reporting

- Regular updates with pictures, videos, or measurement reports

- A dedicated account manager or engineer you can speak to directly

Why it matters: Good communication saves time, prevents misunderstandings, and ensures you stay in control of the project even from overseas.

FAQs on Working with Chinese Injection Molders

If you’re considering sourcing injection molding services from China, you probably have some concerns. Here are answers to the most common questions buyers ask before choosing a supplier.

How do I protect my IP when working with a Chinese supplier?

Protecting your intellectual property (IP) is a valid concern, especially if you’re sharing custom part designs or proprietary product concepts. While the risk can’t be eliminated completely, there are proven ways to minimize exposure and retain control:

1. Use an NNN Agreement, Not Just an NDA

An NNN Agreement (Non-Disclosure, Non-Use, Non-Circumvention) is more enforceable in China than a typical Western NDA. It prevents the supplier from:

- Disclosing your information to third parties

- Using your design for their own production

- Selling your product behind your back

Make sure it’s written in Chinese and enforceable under Chinese law.

2. Verify the Legal Entity

Ensure you’re working with a registered Chinese manufacturer, not just a trading company or sourcing agent.

- Ask for their business license

- Check their physical address and factory ownership

- Look for past clients in IP-sensitive industries like medical or automotive

3. Control Access to Full Designs

Don’t send complete assemblies to one vendor unless necessary.

- Use modular files or partial drawings in the early stages

- Only share full data after signing formal contracts and vetting trust

4. Register Your IP in China

If your product is patentable, consider registering it with the China National Intellectual Property Administration (CNIPA).

- Trademark protection also applies—register your brand name and logo locally

- China uses a first-to-file system, so early action matters

In short: Choose experienced exporters with clean IP histories, use enforceable agreements, and be strategic with information sharing. Many reputable molding companies in China, such as TDLmould or HanKing Mould, understand Western IP concerns and are used to working under NDAs and NNNs.

How much does injection molding cost in China?

Injection molding costs in China vary widely depending on your part size, material, complexity, and production volume. However, the country remains a cost-effective choice due to lower labor costs, mature supply chains, and high manufacturing efficiency.

Typical Cost Breakdown

| Cost Component | Estimated Range (USD) |

| Injection mold (tooling) | $1,000 – $30,000+ (one-time) |

| Unit cost (per part) | $0.10 – $5.00+ (for high-volume runs) |

| Sampling & testing | $100 – $500 |

| Post-processing (e.g., painting, printing) | $0.05 – $1.50+ per part |

Tip: Always ask for a detailed quote that separates mold cost, part cost, material, and shipping. Trusted suppliers usually provide transparent breakdowns to help you budget accurately.

What files or information do I need to start a project?

To get an accurate quote and start production, most Chinese injection molding suppliers will ask for:

- 3D CAD file (STEP/STP preferred)

- 2D drawings with tolerances (PDF or DWG)

- Material specifications (e.g., ABS, PC, PA66)

- Estimated order volume (for quoting mold and per-part cost)

- Surface finish or special requirements (e.g., texture, color, logo)

- Target delivery time

Tip: The more detailed your files, the faster and more accurate the quote will be.

How do I know if the company truly has in-house capabilities and not just outsourcing my order?

When sourcing injection molding services from China, one common concern is whether you’re dealing with a real manufacturer or a middleman. Many suppliers claim full in-house capabilities but actually subcontract the work, adding risk, delays, and quality inconsistencies.

Here’s how you can verify if a supplier truly handles production themselves:

- Ask for real factory photos or walk-through videos showing machines, mold workshops, and assembly areas.

- Request a live video tour to observe equipment in use and staff at work.

- Look for specific machine details—brands (e.g., FANUC, YIZUMI), tonnage range, or cleanroom setups indicate hands-on operations.

- Inquire about average lead times—in-house production usually allows for faster, more predictable delivery.

- Check for certifications (e.g., ISO 9001) and ensure they’re registered under the factory’s name, not a trading company.

A trustworthy manufacturer won’t hesitate to provide this information. If the responses are vague or inconsistent, it’s a strong warning sign.

Will I lose control over the mold once it’s built in China?

This is a valid concern, especially for first-time buyers. When you invest in a mold, you should retain ownership. But in practice, some Chinese suppliers may restrict access, reuse molds, or withhold them if disputes arise.

Here’s how to maintain control:

- Clarify ownership in writing: Make sure your contract or purchase order explicitly states that you own the mold, even if it stays at the supplier’s facility.

- Negotiate a mold storage agreement: Include terms about usage limits, access rights, and what happens if you stop production.

- Ask for mold serial numbers and engraving: Have your company name or unique ID engraved into the mold to prevent unauthorized reuse.

- Choose suppliers with a mold return policy: Some factories agree to return the mold at your request (often after a minimum run or at your expense).

With proper agreements and clear communication upfront, you won’t lose control, no matter where the mold is made.

Final Thoughts

Choosing the right injection molding partner in China isn’t about picking the cheapest quote. It’s about finding the right fit for your industry, part complexity, and growth plans. The companies listed here offer a strong starting point. What matters next is how you engage, evaluate, and build long-term trust.