Delays in tooling can derail even the best-planned projects. When production molds take months to complete, schedules slip, and market opportunities may be lost.

Rapid injection molding was developed to solve this exact challenge. It allows you to receive production-grade plastic parts in a fraction of the usual time, keeping design validation and pilot builds on track. In this guide, we’ll explain what rapid injection molding is, outline the process, and share when it makes the most sense to use it — so you can make informed decisions for your next project.

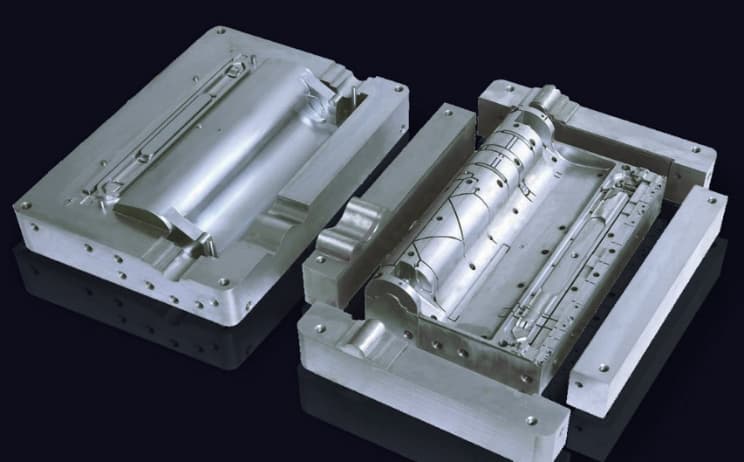

What Is Rapid Injection Molding?

Rapid injection molding is a manufacturing process that uses simplified, quickly machined molds (often made of aluminum or soft tool steel) to produce production-grade plastic parts in a much shorter lead time than traditional molding. Instead of waiting months for a hardened steel production tool, you can have a working mold and first shots in as little as 7–15 days.

This method is sometimes called rapid tooling because the focus is on building the mold fast. Compared with full production tooling, rapid tooling typically has a shorter lifespan — around 50,000 to 100,000 shots. Yet it is ideal for prototypes, pilot runs, and low-volume bridge production.

In short, rapid injection molding bridges the gap between early prototyping and full-scale production. You get parts made from the same resins you will use in mass production, allowing you to validate performance and move your project forward without unnecessary delays.

How the Quick Turn Molding Process Works

Quick Turn injection molding follows a streamlined workflow that focuses on speed without compromising part quality. Here’s how it typically works:

1. RFQ & DFM Review

You start by sending your 3D CAD files and requirements. Within about 24 hours, the engineering team reviews your design for manufacturability — checking draft angles, wall thickness, gate locations, and potential risk areas. You receive a quote and a clear DFM report so you can adjust your design before cutting steel.

2. Rapid Tooling Fabrication

Once the design is approved, the mold is built using aluminum or soft steel. High-speed CNC machining and simplified mold bases shorten the build cycle. Cooling channels and parting lines are optimized to keep lead times tight while maintaining accuracy.

3. T1 Sample Production

The first molded parts — known as T1 samples — are produced, usually within 7–15 days of order confirmation. These samples are used to check dimensions, fit, and surface finish. If minor adjustments are needed, they are made quickly to keep the project on track.

4. Low-Volume Production

After approval, the mold runs the required quantity, whether it’s 50 parts for pilot testing or several thousand for bridge production. The same process parameters are maintained for consistent quality from the first to the last part.

5. Inspection, Shipping & Support

Parts are inspected, packaged, and shipped to your location. Dimensional reports, FAI documentation, or compliance certificates (RoHS, REACH) are provided when requested.

Advantages of Rapid Injection Molding

Rapid injection molding is designed to keep projects moving forward. Instead of waiting for a hardened steel production tool, you can move quickly from CAD design to molded parts and use real data to guide your next decision.

1. Shorter Lead Times

In product development, time is everything. Rapid injection molding shortens the tooling phase dramatically — first shots are typically ready in 7–15 days, compared to 8–12 weeks for a traditional mold. This means you can validate part design, test assemblies, and start pilot builds while your competitors are still waiting for tooling to finish. For industries with aggressive launch schedules, shaving weeks off the timeline can make the difference between leading the market and playing catch-up.

2. Lower Tooling Costs

Because rapid tooling uses aluminum or soft tool steel, machining is faster and less expensive. You avoid the high cost of hardened steel molds until your design is finalized. This is particularly valuable if you expect design changes: modifying an aluminum tool is quicker and far cheaper than reworking a production mold. Many teams use rapid injection molding specifically to de-risk design — they spend less up front, refine the design based on real parts, and invest in the full tool only when they are confident nothing major will change.

3. Production-Grade Materials

Unlike 3D printing or urethane casting, rapid injection molding uses the same resins you’ll run in mass production — ABS, PC, PP, Nylon, POM, TPE, even specialty engineering plastics. This matters because you get accurate data on strength, flexibility, chemical resistance, and surface finish. You can run functional tests under real operating conditions and trust that the results will translate to your final product.

4. Flexible Volumes

Rapid injection molding fills the gap between prototyping and mass production. Whether you need 50 parts for early fit checks or 5,000 parts to keep your assembly line running while waiting for a production mold, the process scales to meet demand. This flexibility prevents supply chain interruptions and allows you to launch limited runs or test the market without committing to a full production investment.

5. Reduced Project Risk

Catching problems early is far less expensive than fixing them later. Rapid injection molding lets you build and test parts quickly, uncovering issues with part geometry, assembly, or performance before you invest in a full-scale tool. If adjustments are needed, you can make them immediately and rerun the tool — avoiding costly delays and scrap during mass production.

Quick Comparison: Rapid vs. Traditional Injection Molding

| Factor | Rapid Injection Molding | Traditional Injection Molding |

| Lead Time | 7–15 days to T1 samples | 8–12+ weeks to first shots |

| Tooling Material | Aluminum / Soft Steel | Hardened Steel |

| Tooling Cost | Lower (ideal for prototypes & bridge tools) | Higher (built for high-volume production) |

| Typical Volume | 50 – 10,000+ parts | 50,000+ parts |

| Design Flexibility | Easy to adjust after first samples | Changes require major rework, costly & slow |

When to Use Rapid Injection Molding

Rapid injection molding is not for every project — but when speed and flexibility matter, it can be the smartest option. Here are the most common situations where it adds value:

Functional Prototypes

When you’ve moved beyond early 3D-printed models, you need parts that match the material properties of production. Rapid injection molding gives you ABS, PC, Nylon, or other engineering plastics molded to spec, so you can evaluate strength, snap-fits, and overall performance. Typical runs for this stage range from 20 to 200 parts, enough for lab testing and internal reviews.

Bridge Production

Production molds can take months to complete. If your assembly line or market launch cannot wait, rapid tooling lets you produce 500–2,000 parts to fill the gap. This keeps your project on schedule and prevents downtime while the full production tool is being built.

Pilot Runs

Before ramping up to full production, many teams run a pilot batch to validate processes, qualify suppliers, and catch last-minute issues. Rapid injection molding is ideal for 200–1,000 parts that go through real assembly, packaging, and shipping, revealing any problems early without risking a massive scrap event.

Market Testing & Early Launches

If you’re gauging customer response or demonstrating to investors, you need production-quality parts — not mockups. Rapid injection molding allows you to build small batches (100–500 parts) with the exact look, feel, and performance of your final product. You can collect feedback and refine before committing to mass production.

Limitations and Considerations

Rapid injection molding delivers speed, but it’s important to understand its practical limits before choosing it for your project. Knowing how tool life, material compatibility, and design readiness affect results will help you set realistic expectations and avoid costly changes later.

Tool Life

Rapid tools are usually cut from aluminum or soft steel, which makes them fast to build but limits their lifespan. Expect 50,000–100,000 cycles on average. This is enough for prototypes, pilot runs, and bridge production — but not for full-scale production where hundreds of thousands of shots are needed. If your forecast shows very high volumes, going straight to a hardened steel tool may save you time later.

Material Compatibility

Most standard resins such as ABS, PC, and PP work well in rapid tooling. However, abrasive or high-temperature materials (e.g., glass-filled nylon, PEEK) wear aluminum tools faster and can reduce tool life. In those cases, upgrading to a harder tool steel or planning for more frequent maintenance can keep production consistent.

Design Readiness

Rapid injection molding works best when your part design is close to final. Small tweaks can be made quickly, but major geometry changes may require re-cutting the tool. A thorough DFM review before starting tooling helps catch issues early and prevents costly rework later.

Cost Factors in Rapid Injection Molding

Even though rapid injection molding is more cost-effective than building a full production tool, several factors still drive the overall price. Understanding these will help you make better design choices and avoid overspending.

Tooling Material and Complexity

The mold itself is the largest single cost component. Aluminum tools are cheaper and faster to machine than P20 or H13 steel tools, but they wear faster. Complex tooling features — such as lifters, side actions, or unscrewing cores — add both machining time and cost. If your design allows, keeping the tool simple is the fastest way to save money.

Part Geometry and Quantity

Thin walls, deep ribs, and tight tolerances require slower machining and careful polishing, which adds to tooling cost. The number of parts you order also matters: the more shots you run, the lower your per-part cost becomes because tooling cost is spread across a larger quantity. For very low quantities, consider whether 3D printing or urethane casting might be more economical.

Material and Surface Finish

Engineering resins vary widely in price. Commodity plastics like PP or ABS are inexpensive, while high-performance materials like PEEK, PSU, or glass-filled nylons can significantly raise the cost per part. Likewise, cosmetic finishes such as SPI-A polishing or Mold-Tech texturing require more tooling work and add to the price.

Tips for Optimizing Costs

- Run a DFM Review Early: The most effective way to control rapid injection molding costs is to start early — ideally at the design stage. A thorough DFM review at this point can reveal opportunities to simplify the mold, such as adding proper draft angles or removing undercuts that require side actions. Each change you make here reduces machining time and keeps tooling lean.

- Maintain Uniform Wall Thickness: Consistent, well-balanced walls not only mold more easily but also shorten cycle time and reduce the risk of warpage. Fewer defects mean less scrap and lower overall part cost.

- Minimize Complex Features: Side actions and deep cores add both cost and lead time; eliminating them wherever possible speeds up mold fabrication and makes future maintenance easier. When complexity is unavoidable, discuss it with your tooling partner early — sometimes a design tweak can achieve the same function with a simpler mold.

- Optimize Gate and Parting Line Placement: Finally, think about how the part will fill. Proper gate placement and parting line design improve flow, reduce cosmetic defects, and minimize the number of rejects you’ll see in first-shot inspection. Every rejected part adds hidden cost. So, designing for good mold flow from the start is a direct cost saver.

When you combine thoughtful design with manufacturability reviews, you get a tool that runs faster, lasts longer, and produces good parts with minimal rework — keeping both your schedule and budget under control.

Rapid Injection Molding vs. Other Methods

Rapid injection molding isn’t the only way to make low-volume plastic parts — but it often strikes the best balance of speed, material choice, and production quality. Here’s how it compares with other common methods.

Compared to 3D Printing

3D printing is excellent for early-stage prototypes and very complex geometries, but its parts rarely match the mechanical properties or surface finish of molded components. Rapid injection molding produces parts from the same resins used in mass production, which means you can trust strength, flexibility, and appearance data. While 3D printing can deliver a handful of parts in days, it becomes expensive at higher quantities, where molding quickly becomes more economical.

Compared to Urethane Casting (Vacuum Casting)

Urethane casting is useful for very small batches — typically under 50 pieces — and can replicate good cosmetic quality. However, silicone molds wear out quickly and the material options are limited to urethanes. If you need parts in engineering-grade plastics or runs of several hundred or thousand pieces, rapid injection molding offers better consistency and durability.

Compared to Traditional Injection Molding

Traditional injection molding is still the standard for high-volume production, but it comes with long lead times and higher upfront costs due to hardened steel tooling. Rapid injection molding uses aluminum or soft steel tools that are faster to machine, so you get parts weeks earlier. Once your design is stable and demand is high, you can transition to a full production mold for maximum longevity.

Quick Comparison Table

| Factor | Rapid Injection Molding | 3D Printing | Urethane Casting | Traditional Injection Molding |

| Lead Time | 7–15 days to first shots | 1–5 days | 1–2 weeks | 8–12+ weeks |

| Tooling Cost | Low to moderate | None | Low | High |

| Part Cost (per unit) | Low for 50+ parts | High for >10 parts | Moderate for 20–50 parts | Lowest for very high volumes |

| Material Options | Full range of thermoplastics | Limited polymers, not always production-grade | Urethanes only | Full range of thermoplastics |

| Surface Finish | Production quality | Rougher, needs post-processing | Good but limited texture options | Production quality |

| Best For | Prototypes, pilot runs, bridge production (50–10,000 parts) | Concept models, early design validation | Very small runs, cosmetic prototypes | High-volume production (50,000+ parts) |

Quality and Documentation

Speed is valuable only if you can trust the parts you receive. Rapid injection molding projects still follow a controlled process to ensure every batch meets your requirements — and when needed, we provide full documentation to support regulated industries.

During production, key dimensions are checked against your CAD model, and critical features are verified before the run is completed. For projects that require formal validation, we can deliver First Article Inspection (FAI) reports, dimensional inspection data, and process capability summaries. These give you confidence that parts meet spec before they leave the factory.

Compliance is just as important. If you are in medical, automotive, or electronics industries, we can provide RoHS and REACH certificates, material data sheets, and other regulatory documentation. Having these files in hand shortens your internal approval cycle and helps you pass audits without delay.

By combining fast delivery with documented quality control, rapid injection molding becomes more than a stopgap — it’s a reliable way to get parts you can actually use in production, prototypes, or pilot builds without compromising compliance.

How to Get Started

Begin by preparing your 3D CAD files, target quantity, preferred material, and any surface finish requirements. Once we have these, our engineers perform a DFM review and send you both a quote and feedback — typically within 24 hours. This early review highlights opportunities to simplify the design, reduce cost, and avoid tooling issues before we cut metal.

After you approve the proposal, we move directly into tooling and molding, keeping you updated at every step. Parts are inspected, packaged, and shipped worldwide, with dimensional reports or compliance documents available if needed.

By sharing your project details early, you can go from design to T1 samples in as little as 7–15 days, instead of waiting months for a traditional mold.

Final Thoughts

Rapid injection molding is one of the fastest ways to turn a finished design into production-grade parts. It helps you validate your design, run pilot builds, and keep your launch on schedule — without committing to the time and cost of a full production tool.

If you’re ready to move your project forward, now is the time to act. Share your CAD files and requirements, and our team will provide a quote and DFM review within 24 hours.

Ready to get parts fast?

Start your rapid injection molding project today — Request a Quote and get your first parts in as little as 7–15 days.

FAQs about Rapid Injection Molding

How fast can I get parts with rapid injection molding?

You can typically receive T1 samples in 7–15 days after approving the DFM review and quote. Once the design is confirmed, low-volume production usually follows within another few days. This rapid turnaround keeps your project moving forward while traditional tooling would still be in progress.

How long will a rapid tool last?

A rapid tool made from aluminum or soft steel typically lasts 50,000–100,000 cycles before showing significant wear. The exact lifespan depends on part geometry, resin choice, and how well the tool is maintained. For example, glass-filled or high-temperature materials can shorten tool life, while regular maintenance can keep it running longer. If your project requires higher volumes, you can upgrade to P20 or H13 steel to extend the tool’s life and support bridge or early mass production.

What materials can I use for rapid injection molding?

Most engineering-grade thermoplastics are available for rapid injection molding, including ABS, PC, PP, Nylon (PA), POM, and TPE. Because these are the same resins used in full production, you can accurately test part strength, flexibility, and appearance before scaling up. Specialty materials and custom colors are also possible if specified during the quoting stage.

What is the typical production volume for rapid injection molding?

Rapid injection molding is ideal for runs from 50 parts up to 10,000 or more. It’s perfect for functional prototypes, pilot runs, and bridge production while you wait for a full production mold. If your forecast shows very high annual volumes, moving to a hardened steel tool is usually more cost-effective in the long run.

Can I make design changes after the first run?

Yes, small design adjustments are possible after the first run, and rapid tools are relatively easy to re-cut. However, major geometry changes may require significant tooling work or even a new mold, which adds cost and time. For best results, finalize critical dimensions and features during the DFM review stage so that most changes can be avoided once production begins.