SLA 3D Printing Service

Produce smooth, detailed prototypes and transparent models with layer thickness as fine as 0.05 mm. Get your parts in as fast as 2 days.

SLA 3D Printing Services

What Is SLA 3D Printing

Stereolithography (SLA) is one of the most precise 3D printing technologies available. It works by using a laser to cure liquid thermoset resin layer by layer, building your part with exceptional resolution and smooth surfaces. With layer thickness as fine as 0.05 mm, SLA can capture sharp edges, intricate features, and tight tolerances that other 3D printing processes may struggle to achieve.

This technology is ideal when you need appearance models, transparent prototypes, or finely detailed components. Because SLA parts come off the printer with a smooth, nearly injection-molded finish, they are easy to paint, polish, or use as master patterns for molding.

SLA 3D Printing Capabilities

Capability | Specification |

|---|---|

Layer Thickness | 0.05 – 0.1 mm layer resolution for sharp edges and fine details |

Typical Tolerances | ±0.1 mm or ±0.1% of nominal dimension — ideal for tight assemblies |

Maximum Build Size | Up to 500 × 500 × 400 mm (or machine-dependent) — print large parts in a single piece |

Material Options | Standard, Clear, Tough, High-Temp, Castable, Flexible resins |

Surface Finish | Smooth, paint-ready surface straight off the printer; easily polished or coated |

Batch Capability | From one-off prototypes to small production runs — scalable without tooling costs |

Upload your CAD file to get a free DFM review — we’ll optimize print orientation and support structures to save you time and cost.

SLA Material Options

We offer a wide selection of engineering-grade SLA resins to match your project requirements.

Material | Key Properties | Typical Applications |

|---|---|---|

Standard Resin | Standard Resin | Concept models, appearance prototypes |

Clear Resin | High transparency, polishable to near-optical clarity | Fluid flow visualization, light guides, optical housings |

Tough Resin | Improved impact strength and durability | Functional prototypes, snap-fit parts, jigs & fixtures |

High-Temp Resin | Heat deflection up to 200 °C+ | Mold inserts, thermal testing, and under-the-hood components |

Flexible Resin | Rubber-like flexibility, good tear strength | Seals, gaskets, wearable prototypes |

Castable Resin | Burns out cleanly for investment casting | Jewelry patterns, dental applications |

Not sure which material is best? Share your CAD model and performance requirements with us — our engineers will recommend the most cost-effective resin for your part’s strength, appearance, and function.

Surface Finish Options for SLA Parts

SLA parts already have a smooth, near-injection-molded surface straight off the printer. Post-processing can take them even further — improving appearance, functionality, and performance.

Finish Option | What It Does | Best For |

|---|---|---|

Standard (As-Printed) | Smooth matte surface with visible but fine layer lines | Functional prototypes, internal components |

Sanding & Polishing | Removes layer lines, achieves near-mirror finish | Appearance models, display prototypes |

Painting & Coating | Adds custom color, improves aesthetics, and UV protection | Marketing samples, end-use covers |

Clear Polishing | For transparent resins — increases optical clarity | Light pipes, fluid visualization models |

Plating or Coating (Optional) | Adds a metal-like appearance or conductivity | Decorative parts, EMI shielding |

For the highest clarity or cosmetic quality, we recommend combining sanding, polishing, and painting. This can make your SLA part look virtually indistinguishable from an injection-molded part.

Applications of SLA

Here are the most common ways our customers use it.

Appearance Prototypes

Create high-resolution, smooth prototypes that look and feel like final production parts. Perfect for design reviews, investor presentations, and marketing samples where aesthetics matter.

Transparent and Clear Parts

SLA excels at printing transparent components, which can be polished to near-optical clarity. Ideal for light pipes, fluid flow visualization models, and optical housings.

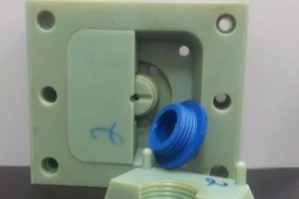

Master Patterns for Molding

Use SLA parts as master patterns for urethane casting or silicone molding. The smooth surface ensures better mold quality and reduces post-processing work.

Medical and Dental Models

Print detailed anatomical models, dental aligner molds, or surgical guides with high accuracy, supporting research, education, and patient-specific planning.

Small-Batch Production

Bridge the gap between prototyping and injection molding. SLA allows you to produce short runs of intricate components without the cost of tooling.

If you’re unsure whether SLA is the right process for your part, upload your CAD file. Our engineers will recommend the best technology to balance accuracy, cost, and lead time.

Why Choose Us

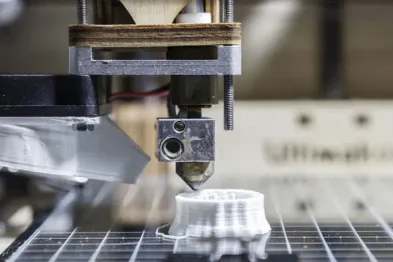

Industrial-Grade SLA Printers

We operate high-end SLA machines capable of large build volumes and consistent results — perfect for prototypes and small-batch production.

ISO-Certified Quality Control

Every part is inspected for dimensional accuracy and surface finish, following strict ISO standards to ensure repeatability and reliability.

Expert Finishing Team

Our technicians can sand, polish, and finish your parts to achieve optical clarity and showroom-quality appearance.

NDA Protection

Your designs are handled confidentially. We can sign an NDA before review and use secure file transfer systems to keep your IP safe.

Partner with Us for SLA 3D Printing Services

Our Equipment

CMM

Inspection

High Speed CNC Machines

Double-Head EDM Machines

EDM

Workshop

CNC machining Workshop

Plastic Injection Molding Room

Mirror EDM Machining

Mould Spotting Machine

Plastic Injection Team

Meet Our Expert Team: The Driving Force Behind TDL Mold’s Innovative Solutions.

Our SLA 3D Printers

We run a fleet of industrial-grade SLA machines designed for precision, repeatability, and speed. This allows us to handle everything from one-off prototypes to large, complex production parts.

Our Other 3D Printing Processes

We have additional 3D printing technologies available.

MJF takes powder-bed printing further by using fusing agents and infrared energy for uniform mechanical properties and faster production cycles.

- Short-run production where part consistency matters

- Complex geometries with fine details and smooth, semi-matte finish

- Economical per-part cost at higher volumes compared to SLS

FDM builds parts by extruding molten thermoplastic layer by layer, making it one of the most cost-effective and widely used 3D printing processes.

- Functional prototypes made from engineering-grade plastics like ABS, ASA, or Nylon

- Large, durable parts with good strength for jigs, fixtures, and tooling

- Fast, affordable iterations early in the design cycle

SLS fuses nylon powder using a laser, building parts layer by layer without support structures. This makes it perfect for complex shapes and assemblies.

- Durable, functional prototypes for mechanical testing

- Snap-fit and moving assemblies thanks to excellent strength and flexibility

- Small-batch production without the cost of molds

FAQ's

Stereolithography (SLA) is a high-resolution 3D printing technology that uses a UV laser to cure liquid thermoset resin, layer by layer, into a solid part. Each layer is precisely traced by the laser, allowing SLA to achieve extremely fine details, sharp edges, and smooth surfaces with layer thicknesses as low as 0.05 mm.

This process is ideal for producing appearance prototypes, transparent models, and parts with tight tolerances. Because SLA parts come off the printer with a nearly injection-molded finish, they require minimal sanding before painting or polishing.

If you’re not sure whether SLA is the right process for your part, share your CAD file with us. We can review your design and suggest the most efficient manufacturing approach to meet your accuracy, surface finish, and cost requirements.

With our industrial SLA machines, we can print parts up to 500 × 500 × 400 mm (19.7 × 19.7 × 15.7 in) in a single build. This large build volume lets you create sizable prototypes, housings, or models without splitting them into multiple pieces.

If your design is larger than the maximum build size, we can section the part, print it in multiple segments, and bond them together with minimal visible seams. This approach works well for architectural models, full-scale display parts, or very large prototypes.

SLA is one of the most precise 3D printing processes available. Typical dimensional accuracy is ±0.1 mm or ±0.1% of the nominal dimension (whichever is greater) on well-supported features. This makes SLA an excellent choice for prototypes, master patterns, and small production parts where tight fits matter.

Several factors can influence final accuracy, including part geometry, wall thickness, print orientation, and post-curing. To achieve the best results, we optimize orientation and support structures before printing and recommend adding critical dimensions to your 2D drawings for verification.

If your project requires even tighter tolerances, let us know. We can adjust process parameters or add post-machining to meet your specifications.

SLA parts are known for their smooth, almost injection-molded surface finish. Layer lines are very fine — typically 0.05–0.1 mm — and most parts are ready for painting or light sanding straight off the printer.

If your project demands a showroom-quality appearance or optical clarity, additional post-processing can take the finish even further. Sanding, polishing, and clear coating can eliminate visible layer lines and achieve a near-mirror surface. For transparent parts, we offer polishing services to bring them to near-optical clarity.

Tip: Combining sanding and painting or polishing not only improves appearance but also protects the part from UV exposure and surface wear.

Yes — one of the biggest advantages of SLA is its ability to print in clear resins. Straight off the printer, clear SLA parts have a frosted appearance, but they can be sanded and polished to achieve near-optical transparency.

Our finishing team uses a combination of progressive sanding, polishing compounds, and optional clear coating to bring out clarity and smoothness. This is ideal for fluid flow visualization models, light pipes, lenses, and display components where seeing internal features is critical.

Tip: For the best clarity, we recommend designing with uniform wall thickness and avoiding unsupported overhangs, which can leave visible marks after support removal.

Most SLA prototypes can be shipped in as little as 2–3 business days once your design is approved. For small-batch production or parts requiring extensive post-processing (such as polishing or painting), lead times are typically 5–7 business days.

If you have a tight deadline, we offer expedited printing and shipping services. Let us know your target delivery date when requesting a quote, and we’ll prioritize your order to keep your project on schedule.

Yes — we take confidentiality very seriously. We can sign a Non-Disclosure Agreement (NDA) before reviewing your CAD files. All files are stored securely, accessed only by our engineering team, and permanently deleted upon request.

Our quoting and production systems are designed with data security in mind, so you can confidently share prototypes, production parts, or sensitive designs knowing your intellectual property is fully protected.