Custom Mold Design Services

- DFM & Mold Flow Analysis for manufacturability assurance

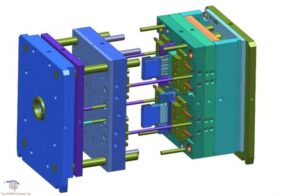

- 3D mold design with precise cooling and gating systems

- Optimized tooling structure for long mold life and fast cycle time

- Expertise in multi-cavity, hot-runner, and insert mold design

Custom Mold Design Services in China

TDL’s mold design team has 20+ years of experience in creating custom molds that meet the specific needs of your project.

Advantages

Advantages of Working With TDL

20 + Years Experience

With 20+ years of experience in mold design and manufacturing, TDL successfully delivered 500+ injection molding tooling projects for 200+ clients across automotive, medical, electronics, and aerospace industries.

Design Optimization

We apply DFM to make your design easier and more cost-effective to produce, and DFMEA to spot and prevent potential risks before manufacturing. Together, they ensure efficient and reliable mold production.

Professional Engineering Team

TDL mold design & engineering team has 34 skilled engineers to provide technical support for plastic mold making and plastic processing.

Advanced Technology

We leverage cutting-edge CAD/CAM software and 3D simulation tools to design and produce high-precision molds with complex structures.

One-Stop Solution

TDL offers a one-stop solution to meet all customers' demands for plastic mould and customized plastic products manufacturing.

Quick Response & Support

We provide fast and responsive services, quickly solving issues and adjusting designs and production schedules based on customer needs.

Products

What Products' Molds We Have Designed?

We specialize in mold design, delivering high-precision solutions for medical, automotive, and electronics industries. From complex medical devices to automotive parts and electronic components, our molds ensure exceptional accuracy, durability, and consistency.

Case Studies

See how TDL turns demanding requirements into successful mold projects.

How Does TDL Revolutionize Plastic Tester Mold Manufacturing?

TDL excels in plastic tester mold manufacturing by integrating innovation, precision, and expertise. They meet high industry standards and client demands through advanced techniques, rigorous quality control, and efficient solutions, ensuring excellence in every mold produced.

How Does TDL Achieve Precision in Automotive Door Handle Mold Manufacturing?

TDL excels in automotive door handle mold manufacturing by leveraging advanced technology and innovative solutions. They meet stringent client requirements for precision, quality, and short lead times through meticulous design, mold flow analysis, and rigorous quality control, ensuring superior performance and aesthetic standards.

How Does TDL Excel in Low-Pressure Injection Mold Manufacturing?

TDL excels in precision low-pressure injection mold manufacturing, transforming complex customer requests into high-quality molds using advanced techniques, rigorous quality control, and innovative solutions to overcome challenges.

How Does TDL Achieve Precision in Knob Lock Mold Manufacturing?

TDL excels in manufacturing knob lock molds by leveraging advanced techniques, precision engineering, and rigorous quality control. Meeting stringent client requirements, they ensure high durability, efficient production cycles, and cost-effectiveness, showcasing their expertise in delivering exceptional mold solutions.

How Does TDL Lead the Way in Automotive Tank Mold Manufacturing?

TDL excels in automotive tank mold manufacturing by integrating precision, innovation, and advanced technology. Their expertise ensures high-quality, efficient, and durable molds that meet stringent industry standards and client requirements, overcoming challenges with strategic solutions and rigorous quality control.

How Does TDL Achieve Precision in Helical Gear Mold Manufacturing?

TDL excels in helical gear mold manufacturing by combining precision engineering, advanced technology, and rigorous quality control. Meeting stringent client demands, TDL delivers high-accuracy molds that ensure seamless gear transmission, addressing complex challenges with innovative solutions and maintaining industry-leading standards.

Our effective mold design solutions help you reduce rework and development costs.

Mould Design Process

Project Plan

A project plan outlines scope, tasks, timeline, resources, responsibilities, risks, stakeholder communication, review points, and budget.

DFM Report

A DFM report assesses a product's design for efficient, cost-effective manufacturing, analyzing process, material, geometry, tolerances, and costs.

Mold 2D/3D Design

Mold 2D/3D Design involves creating, simulating, and testing a mold design using CAD software for efficient and accurate manufacturing.

Customer Approve of Mould Design

The Customer Approval of Mould Design stage involves customer review and approval of the mold design before manufacturing begins.

We accept a wide range of 2D and 3D file formats, including IGES (.igs), STEP (.stp), DXF (.dxf), DWG (.dwg), and Parasolid (.x_t, .x_b). For any upload issues, contact us for assistance.

Diverse Industry Solutions

Our expert engineering team offers tailored solutions for a wide range of industries, utilizing innovative technology and design strategies to provide optimal results for our clients.

Medical molds

Specialized innovations focused in meeting the unique needs of the medical industry

Electric & Electronics

Specialized molds for complex electric and electronics applications.

Mould Design Team

Meet Our Expert Team: The Driving Force Behind TDL Mold’s Innovative Solutions.

Related Topics

The Complete Guide to Mold Flow Analysis

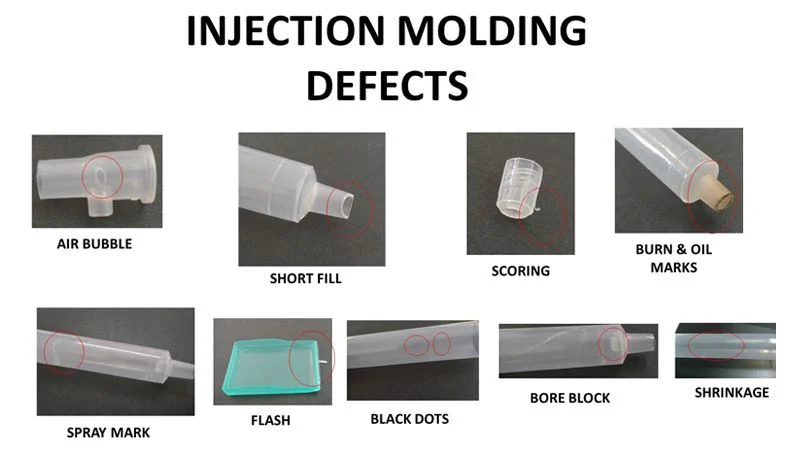

You’ve finalized the part design—but once it enters tooling, problems begin: short shots, warpage, uneven filling. Sound familiar? These issues often trace back to one thing: no mold flow analysis was done before tooling. At our mold manufacturing facility, we treat MFA as a standard, not an extra, because it prevents exactly these outcomes. In […]

Comprehensive Guide to Designing for Liquid Silicone Rubber (LSR) Molding

FAQ's

Plastic mold design refers to the process of creating a blueprint or specification for the construction of a mold that will be used to manufacture plastic parts or products through a molding process. This crucial step involves careful planning and consideration of various factors to ensure the final mold produces high-quality plastic parts efficiently and accurately.

The plastic molding process involves injecting molten plastic material into a mold cavity, allowing it to cool and solidify, and then ejecting the finished part from the mold. The mold itself is a custom-made tool with a specific shape and configuration that determines the final design of the plastic part.

image source: https://www.plasticmoulds.net

1) Product Design: The first step involves understanding the product or part that needs to be manufactured. This includes its dimensions, shape, material properties, and any functional or aesthetic requirements.

2) Mold Cavity: The mold must be designed with one or more cavities that define the shape of the plastic part. The number of cavities in the mold affects the production rate.

3) Mold Material: Selecting the appropriate material for the mold is essential to ensure durability, temperature resistance, and compatibility with the plastic material being used.

4) Cooling System: Efficient cooling channels are integrated into the mold design to ensure proper and uniform cooling of the molten plastic, reducing cycle time and preventing defects.

5) Draft Angles: Draft angles are included in the mold design to enable easy ejection of the finished part from the mold without damaging the part or mold.

6) Runner System and Gates: The runner system distributes the molten plastic from the injection molding machine to the mold cavities, and the gates control the flow of plastic into the cavities.

7) Ejection System: The ejection system is designed to push or extract the finished part from the mold after the cooling process.

8) Venting: Proper: venting is necessary to allow air and gases to escape from the mold during the injection process, preventing defects like air traps.

9) Parting Line: The parting line is the dividing line between the two halves of the mold. It should be strategically placed to avoid critical features and maintain part consistency.

10) Tolerances and Surface Finish: Mold designers must consider the required tolerances and surface finish for the plastic part and incorporate them into the mold design.

Effective plastic mold design is crucial for achieving high-quality plastic parts, reducing production costs, and maximizing efficiency in the manufacturing process. It requires a combination of engineering knowledge, material expertise, and an understanding of the injection molding process.

There are several types of plastic molds used in the plastic molding industry, each designed to suit different production requirements and part geometries. Some of the common types of plastic molds include:

1) Injection Mold:

Image courtesy: https://www.plastopialtd.com

Injection molds are the most widely used type of plastic molds. They consist of two halves (core and cavity) and are used in the injection molding process. Molten plastic is injected into the mold, cooled, and then ejected as a solid part. Injection molds are suitable for high-volume production and can produce complex parts with high precision.

2) Blow Mold:

Image courtesy: https://www.indiamart.com

Blow molds are used in the blow molding process to create hollow plastic parts, such as bottles, containers, and other hollow shapes. The process involves injecting air into the molten plastic, which forces it to expand and conform to the shape of the mold.

3) Compression molds:

Image courtesy: https://www.iqsdirectory.com

Compression molds are used in compression molding, a process where the plastic material is placed directly into the mold cavity, and then heat and pressure are applied to shape and solidify the plastic.

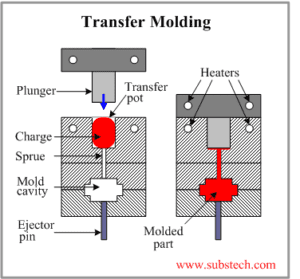

4) Transfer Mold:

Image courtesy: https://www.substech.com

Transfer molds are used in transfer molding, a process similar to compression molding, but the plastic material is preheated in a separate chamber before being forced into the mold cavity through a transfer pot.

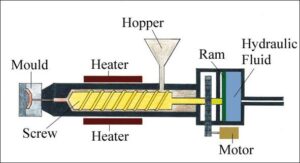

5) Extrusion Mold:

Image courtesy : https://adrecoplastics.co.uk

Extrusion molds are used in the extrusion process to create continuous plastic profiles with a consistent cross-section. The plastic material is forced through a die to produce long shapes like pipes, tubes, and sheets.

6) Thermoforming Mold:

Image courtesy : https://www.indiamart.com

Thermoforming molds are used in the thermoforming process to create thin-gauge plastic products like trays, containers, and packaging materials. The plastic sheet is heated, draped over the mold, and then vacuum-formed into the desired shape.

7) Rotational Mold: .

Image courtesy: https://www.iqsdirectory.com

Rotational molds, also known as rotomolds, are used in rotational molding. The mold is rotated in multiple axes while the plastic material inside melts and coats the inner surface of the mold, forming hollow parts.

8) Insert Mold:

Image courtesy: https://jayconsystems.com

Insert molds are designed to incorporate metal or other components into the plastic part during the molding process. The plastic material is molded around the inserted component, creating an integrated assembly.

9) Overmold:

Image courtesy : https://jayconsystems.com

Overmolding involves using two or more different materials to create a single part. The first material (substrate) is molded first, and then a second material is molded over it to add features or enhance performance.

Each type of plastic mold has its advantages and limitations, and the selection depends on factors such as the type of plastic material, the complexity of the part design, production volume, and cost considerations. Manufacturers choose the most appropriate mold type to achieve the desired end-product efficiently and economically.

image courtesy : https://www.xometry.com

In plastic mold design, various materials are used to construct molds that can withstand the demands of the molding process and produce high-quality plastic parts. The choice of mold material depends on factors such as the molding process, the type of plastic material being used, the expected production volume, and the complexity of the part design. Some commonly used materials for plastic mold design include:

1) Tool Steel: Tool steels are widely regarded as the workhorses of plastic mold design due to their exceptional mechanical properties. They offer high hardness, wear resistance, and toughness, making them well-suited for the high-pressure and abrasive nature of the injection molding process. Tool steels are available in various grades, each with specific advantages. For example, P20 is a popular choice for general-purpose molding applications, H13 is preferred for high-temperature applications, and S7 is used when impact resistance is crucial. 420 stainless steel is also utilized when corrosion resistance is required in certain molding applications.

2) Pre-hardened Steel: Pre-hardened steels like P20 are already heat-treated, providing a good balance of hardness and machinability. Because they come pre-hardened, they eliminate the need for extensive heat treatment during mold manufacturing, reducing lead times and costs. Pre-hardened steels are commonly used for medium to high-volume production.

3) Stainless Steel: Stainless steel molds are ideal for molding applications that involve corrosive plastic materials or environments. The most common stainless steel grades used for molds are 420 and 316, known for their excellent corrosion resistance. These molds are suitable for producing parts that require high hygiene standards, such as medical devices or food-grade products.

4) Aluminum: Aluminum molds are chosen for their excellent thermal conductivity, which allows for faster heat transfer and shorter cooling times during the molding process. This feature is particularly advantageous for reducing cycle times in the injection molding process. Aluminum molds are commonly used for low to medium production volumes or for rapid prototyping where cost considerations are significant.

5) Beryllium Copper: Beryllium copper molds are preferred in applications requiring exceptional thermal conductivity and electrical conductivity. They are particularly useful in molding high-temperature plastics and for applications where precision cooling is essential to achieve intricate part geometries.

6) Brass: Brass molds are relatively softer compared to steel molds and are typically used for low-volume production or prototyping purposes. While they exhibit decent thermal conductivity, their durability is lower than that of steel molds, which limits their use to specific applications or shorter production runs.

- Composite Materials: In some cases, composite materials, such as reinforced epoxy or fiberglass, may be used for molds when producing limited quantities or for specialized applications.

Choosing the appropriate mold material involves considering factors such as the expected production volume, part complexity, molding process requirements, plastic material properties, and budget constraints. Each material has its unique strengths and limitations, and mold designers need to carefully evaluate these aspects to ensure the selected mold material meets the production needs and maintains the quality of the molded plastic parts. Proper maintenance, periodic inspection, and adherence to best practices in mold design and operation are essential to maximize the mold's lifespan and ensure consistent part quality throughout its service life.

The plastic mold design process involves a series of steps to create a detailed blueprint or specification for constructing a mold that will be used to manufacture plastic parts or products. This process requires careful planning, consideration of various factors, and collaboration between designers, engineers, and mold manufacturers. Here are the key steps involved in the plastic mold design process:

1) Product Requirements and Conceptualization: The first step is to understand the requirements of the plastic part or product that needs to be manufactured. This involves gathering information on dimensions, shape, material properties, functional requirements, and any specific design features. Designers work closely with the client or product development team to conceptualize the initial design.

2) Design Feasibility Analysis: Once the initial concept is formed, a feasibility analysis is conducted to evaluate the design's viability for the intended production process and identify any potential challenges. Factors such as moldability, parting lines, draft angles, and undercuts are considered at this stage.

3) Detailed Design and 3D Modeling: With the feasibility analysis complete, the design is further developed into a detailed 3D model using computer-aided design (CAD) software. Designers create the core and cavity shapes, add cooling channels, gating systems, and venting as needed. The 3D model provides a comprehensive visualization of the mold's components and functionality.

4) Material Selection: During the design process, the appropriate mold material is chosen based on factors such as the expected production volume, molding process, plastic material to be used, part complexity, and cost considerations.

5) Mold Flow Analysis (Optional): In some cases, mold flow analysis may be conducted using specialized software to simulate the plastic flow behavior during the injection molding process. This analysis helps identify potential flow-related issues, such as air traps, weld lines, and sink marks, allowing designers to optimize the mold design for improved part quality.

6) Prototype Development (Optional): Depending on the complexity of the design and the level of confidence in the mold concept, a prototype may be created using rapid prototyping techniques (3D printing) to validate the design and make any necessary adjustments.

7) Finalization and Documentation: Once the design is approved, the mold design is finalized, and detailed documentation is created, including technical drawings, specifications, and bill of materials (BOM). This documentation serves as a blueprint for the mold manufacturing process.

8) Mold Manufacturing: The finalized mold design is sent to a mold manufacturer, who uses the design specifications to fabricate the mold. The mold is typically machined from the selected mold material, and various components like cooling channels, ejector systems, and gate inserts are integrated into the mold.

9) Mold Testing and Adjustment: After manufacturing, the mold undergoes testing to ensure it functions as intended. Adjustments may be made to optimize the mold's performance and produce high-quality plastic parts.

10) Production and Maintenance: Once the mold is approved for production, it is used in the plastic molding process to produce the desired plastic parts. Regular maintenance and inspection are conducted to ensure the mold's longevity and consistent part quality.

Throughout the plastic mold design process, effective communication between all stakeholders is vital to ensure that the final mold meets the requirements and achieves the desired results in terms of part quality, production efficiency, and cost-effectiveness.

Designing a plastic mold is a crucial process that requires careful consideration of various factors to ensure the mold's functionality, efficiency, and longevity. Here are the key considerations in designing a plastic mold:

1) Product Design and Functionality: Understanding the requirements and functionality of the plastic part is the foundation of mold design. Analyze the part's shape, dimensions, wall thickness, and any critical features to ensure they can be replicated accurately in the mold.

2) Moldability and Part Design for Manufacturing: Evaluate the part design for moldability. Identify potential challenges like thin sections, sharp corners, complex geometries, and undercuts that might affect the mold's ability to produce the part correctly and efficiently.

3) Material Selection for Mold Construction: Choose the appropriate mold material based on factors such as expected production volume, molding process, plastic material, part complexity, and budget. Common materials include tool steel, pre-hardened steel, stainless steel, and aluminum.

4) Parting Line and Draft Angles: Determine the optimal parting line where the mold's two halves, the core and cavity, will separate. Incorporate draft angles to enable easy ejection of the part from the mold without causing damage.

5) Cooling System Design: Design an efficient cooling system with strategically placed cooling channels to control the mold temperature and ensure uniform cooling of the molten plastic. Proper cooling helps reduce cycle times and improves part quality.

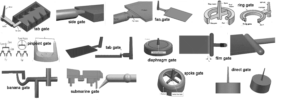

6) Gate Design and Location:

Image courtesy: https://www.plasticmoulds.net

Select the appropriate gate type (e.g., edge gate, pin gate, hot runner system) based on the part's design and requirements. Place the gate in a location that allows for smooth and controlled flow of plastic into the mold cavity.

7) Ejection System Design: Design an effective ejection system to remove the finished part from the mold. Consider the use of ejector pins, sleeves, or other mechanisms to ensure the part is ejected without distortion or damage.

8) Venting: Include proper venting in the mold design to allow air and gases to escape during the injection process. Adequate venting helps prevent defects like air traps and improves part surface quality.

9) Mold Flow Analysis (Optional): Consider conducting mold flow analysis using specialized software to simulate plastic flow during injection molding. This analysis helps identify potential issues and optimize the mold design for better part quality and process efficiency.

10) Tolerances and Surface Finish: Define the required tolerances and surface finish for the plastic part and incorporate them into the mold design to ensure the final part meets the desired specifications.

11) Runner and Sprue Design: Design an efficient runner system to distribute the molten plastic from the injection molding machine to the mold cavities. Optimize the sprue design to minimize material wastage and reduce cycle times.

12) Mold Maintenance and Serviceability: Design the mold for ease of maintenance, inspection, and repair. Consider access to critical components for cleaning and maintenance, which extends the mold's lifespan and ensures consistent part quality.

13) Environmental Impact: Consider sustainable practices in mold design, such as material selection with recycled content, waste reduction strategies, and energy-efficient cooling systems, to minimize the environmental impact of plastic molding processes.

14) Production Volume and Cost Considerations: Take into account the expected production volume and overall cost considerations when making design decisions. Optimize the mold design for cost-effectiveness while maintaining high-quality part production.

15) Testing and Validation: If feasible, create prototypes and conduct testing to validate the mold design before full-scale production. Prototyping allows for adjustments and improvements to be made early in the design process.

By carefully considering these factors in the plastic mold design process, designers can create molds that produce high-quality plastic parts efficiently, economically, and in an environmentally responsible manner. Effective mold design is crucial for successful plastic molding operations and plays a significant role in achieving the desired part quality and production efficiency.

Image courtesy: https://info.crescentind.com

Ensuring the quality of a plastic mold design is crucial for producing high-quality plastic parts efficiently and effectively. Here are some key steps you can take to ensure the quality of your plastic mold design:

1) Clear Design Requirements: Ensure that you have a clear understanding of the requirements for the plastic part or product to be manufactured. This includes dimensions, shape, material properties, functional and aesthetic requirements, and any specific design features.

2) Moldability Analysis: Conduct a thorough moldability analysis of the part design to identify potential challenges and ensure that the design can be effectively replicated in the mold without defects or issues during the molding process.

3) Collaboration and Communication: Foster effective communication and collaboration between design teams, engineers, and mold manufacturers to ensure everyone is aligned on the design requirements and any potential design improvements.

4) Mold Flow Analysis (If Applicable): Consider conducting mold flow analysis using specialized software to simulate the plastic flow behavior during injection molding. This analysis helps identify potential flow-related issues and optimize the mold design for better part quality and process efficiency.

5) Material Selection for Mold Construction: Choose the appropriate mold material based on factors such as expected production volume, molding process, plastic material, part complexity, and budget. Select high-quality materials that offer durability and reliability.

6) Use of Experienced Designers: Employ experienced and skilled mold designers who are well-versed in plastic mold design principles and best practices. Experienced designers can anticipate potential challenges and design molds for optimal performance.

7) Validation through Prototyping: If feasible, create prototypes of the plastic part to validate the mold design before full-scale production. Prototyping allows for adjustments and improvements to be made early in the design process.

8) Design Reviews and Iterative Process: Conduct thorough design reviews with all stakeholders involved in the project. Encourage feedback and iterate on the design to address any identified issues and optimize the mold design.

9) Quality Control Measures: Implement robust quality control measures throughout the mold design process to check for errors, inconsistencies, and adherence to design specifications.

10) Mold Manufacturing and Inspection: Work with reputable mold manufacturers that have a track record of producing high-quality molds. Inspect the manufactured mold thoroughly to ensure it aligns with the design specifications.

11) Maintenance and Serviceability: Design the mold for ease of maintenance, inspection, and repair. Regularly maintain the mold to extend its lifespan and ensure consistent part quality.

12) Testing and Validation during Production: Conduct initial testing and validation runs during production to ensure the mold is producing parts to the desired specifications and quality standards.

13) Continuous Improvement: Encourage a culture of continuous improvement, where lessons learned from each production run are used to refine and enhance future mold designs and processes.

By following these steps and incorporating best practices in plastic mold design, you can ensure the quality of your mold design, leading to successful plastic molding operations and the production of high-quality plastic parts.

The cost of plastic mold design is influenced by various factors that need to be considered during the design process. These factors can have a significant impact on the overall cost of mold production and, subsequently, the cost of manufacturing plastic parts. Here are the key cost factors in plastic mold design:

1) Complexity of the Part Design: The complexity of the plastic part design has a direct impact on the mold design cost. Intricate part geometries, multiple undercuts, thin walls, and complex shapes may require advanced mold features like side actions, lifters, or collapsing cores. These additional features add complexity to the mold design, leading to higher manufacturing and machining costs.

2) Mold Material Selection: The choice of mold material is a significant cost consideration. High-quality tool steels, such as H13 or S7, provide superior durability and wear resistance, but they come at a higher cost compared to more economical options like P20. The decision on mold material depends on factors such as the expected production volume, molding process, plastic material, and budget constraints.

3) Mold Size and Number of Cavities: Larger molds or molds with multiple cavities will generally be more expensive due to increased material and machining requirements. Multi-cavity molds, which produce multiple parts in each molding cycle, can lead to higher initial costs but can be more cost-effective in high-volume production due to increased productivity.

4) Molding Process and Part Volume: Different molding processes have unique mold design requirements and cost implications. For example, injection molding requires precision tooling, while rotational molding relies on less complex molds. The expected production volume also influences the cost-effectiveness of the mold design. For low-volume production, less expensive mold materials or rapid tooling techniques (e.g., 3D printing) might be more suitable.

5) Tolerance and Surface Finish Requirements: Tight tolerances and specific surface finish requirements can impact the mold design complexity and manufacturing processes. Achieving tight tolerances may require additional machining steps and more precise tooling, contributing to higher costs.

6) Mold Complexity and Features: Molds with additional features, such as side actions, lifters, hot runner systems, or complex cooling channels, will have higher costs due to increased design complexity and more extensive machining.

7) Mold Components and Hardware: The selection and quality of mold components and hardware, such as ejector pins, guide pins, bushings, screws, and hot runner systems, can impact the overall cost. High-quality components may have a higher upfront cost but can offer better durability and longer mold life.

8) Mold Manufacturer and Location: The choice of the mold manufacturer and their location can influence the cost. Manufacturers with advanced capabilities, expertise in complex mold designs, or use of advanced technology might charge higher fees. Additionally, the manufacturing location can affect labor and material costs.

9)Mold Maintenance and Serviceability: Designing the mold for ease of maintenance and serviceability can impact the overall cost. Molds that are difficult to maintain or require frequent repairs may result in higher long-term costs.

10) Prototyping and Testing: If prototyping and testing are necessary to validate the mold design, there will be additional costs associated with these processes. However, investing in prototyping can help identify and rectify design issues early on, saving costs in potential rework during mass production.

11) Environmental Considerations: If sustainability factors are taken into account in the mold design, such as using materials with recycled content or adopting eco-friendly manufacturing practices, there may be associated costs. However, embracing environmentally friendly practices can demonstrate a commitment to sustainability and responsible manufacturing.

Balancing the desired quality, functionality, and cost is essential when designing a plastic mold. Working with experienced mold designers, considering different material options, and optimizing the design for the intended production volume can help manage costs effectively while achieving a high-quality mold design that meets the project's requirements.

The time required to design and produce a plastic mold can vary significantly based on several factors. The complexity of the mold design, the mold material, the manufacturing process, the availability of resources, and the expertise of the mold designers and manufacturers all play a role in determining the overall timeline. Here's a general overview of the typical timeframes involved in designing and producing a plastic mold:

1) Mold Design Time: The mold design process can take anywhere from a few weeks to several months, depending on the complexity of the part design and the mold itself. Simple molds with straightforward geometries may be designed relatively quickly, while more intricate molds with complex features may require more time for design, analysis, and optimization.

2) Prototyping and Validation (Optional): If prototyping is part of the process, additional time is needed to produce prototypes of the plastic part and conduct testing and validation. This step is crucial for verifying the mold's performance and making any necessary adjustments before finalizing the design for mass production.

3) Mold Manufacturing Time: The actual manufacturing of the mold typically takes several weeks to months, depending on the mold material and complexity. Machining a mold from steel may require more time compared to using pre-hardened steel or aluminum.

4) Mold Inspection and Testing: Once the mold is manufactured, it undergoes thorough inspection and testing to ensure it meets the design specifications and quality standards. This process may take a few days to a week, depending on the complexity of the mold and the extent of testing required.

5) Production Lead Time: After the mold is validated, it is ready for mass production. The lead time for production depends on factors such as the production volume, cycle times, and manufacturing efficiency. Production lead times can range from days to several weeks, especially for large production runs.

Overall, the entire process of designing and producing a plastic mold can take anywhere from a few weeks to several months. It's important to note that the timeline can be influenced by factors such as the complexity of the part, the availability of resources and materials, the capacity and expertise of the mold manufacturer, and any unforeseen challenges that may arise during the process.

Efficiency in the mold design and production process is crucial for reducing lead times and ensuring timely delivery of molds for plastic manufacturing. Effective communication and collaboration between all stakeholders, including designers, engineers, and mold manufacturers, can help streamline the process and minimize potential delays.

Plastic mold design is continuously evolving with the advent of new technologies, which are revolutionizing various aspects of the design process. These advancements aim to improve efficiency, accuracy, cost-effectiveness, and overall performance in plastic mold design. Here are some ways plastic mold design is evolving with new technologies:

1) Computer-Aided Design (CAD) and Simulation Software:

Image courtesy : https://www.3erp.com

CAD software has been a game-changer in mold design, enabling designers to create detailed 3D models of molds with precision and efficiency. Simulation software allows for mold flow analysis, predicting how molten plastic will behave during injection molding. This analysis helps optimize mold designs to minimize defects and improve part quality.

2) Additive Manufacturing (3D Printing):

Image courtesy: https://www.additivemanufacturing.media

Additive manufacturing, or 3D printing, is transforming mold prototyping and tooling development. Designers can create rapid prototypes of molds using 3D printing, allowing for quicker validation of designs and reducing lead times in the design iteration process.

3) Digital Twin Technology:

Image courtesy: https://www.fastradius.com/resources

Digital twin technology creates virtual replicas of physical molds, enabling real-time monitoring and analysis of mold performance during production. This technology helps optimize mold operation, minimize downtime, and predict maintenance needs.

4) Artificial Intelligence (AI) and Machine Learning:

Image courtesy:https://www.plasticstoday.com

AI and machine learning are being integrated into mold design processes to automate repetitive tasks, enhance design optimization, and predict potential issues during the molding process. These technologies aid in improving efficiency and reducing human errors.

5) Cloud-Based Collaboration and Data Sharing:

Image courtesy: https://www.moldex3d.com

Cloud-based platforms facilitate seamless collaboration among design teams, engineers, and manufacturers, regardless of their location. This allows for real-time sharing of design data, reducing communication delays and streamlining the overall design process.

6) High-Performance Materials and Coatings:

Image courtesy: https://www.pfiinc.com

Advances in material science have led to the development of high-performance mold materials and coatings that offer improved durability, wear resistance, and corrosion resistance. These materials extend the life of molds and improve overall performance.

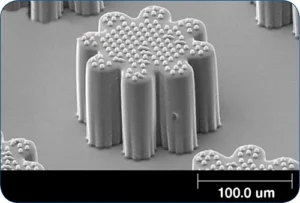

7) Micro and Nano Manufacturing:

Image courtesy: https://www.ptonline.com

Micro and nano manufacturing technologies enable the creation of ultra-precise molds for micro-components and small parts with intricate details. These technologies are essential for industries like electronics, medical devices, and automotive.

8) Internet of Things (IoT) and Industry 4.0:

Image courtesy: https://www.automationalley.com

IoT and Industry 4.0 concepts are being applied to mold design and manufacturing, creating smart factories and connected molds that can monitor and optimize their own performance and maintenance needs.

9) Sustainable and Eco-Friendly Solutions:

Image courtesy: https://www.greatcentralplastics.com

With increasing environmental awareness, new technologies focus on sustainable mold design practices, incorporating eco-friendly materials, energy-efficient cooling systems, and waste reduction strategies.

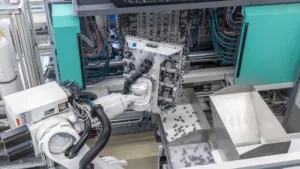

10) Automated Manufacturing and Robotics:

Image courtesy: https://www.kuka.com

Automation and robotics are being utilized in mold manufacturing to streamline the production process, reduce labor costs, and enhance repeatability and precision.

These technologies continue to push the boundaries of plastic mold design, making it more efficient, precise, and sustainable. Mold designers and manufacturers are continuously embracing these innovations to stay competitive, meet market demands, and address the evolving needs of the plastic molding industry.