MJF 3D Printing Service

Produce functional parts in PA12, PA11, or glass-filled nylon with layer thickness as fine as 80 µm and build sizes up to 380 × 284 × 380 mm. Orders ship in as little as 3–5 days.

MJF 3D Printing Service

What is MJF 3D Printing?

Multi Jet Fusion (MJF) is an industrial 3D printing process developed by HP. It fuses nylon powder layer by layer using infrared heat and precision fusing agents. The result is parts with uniform strength in all directions, something that sets MJF apart from other powder-bed technologies.

- No support structures: Parts are surrounded by unfused powder, enabling complex geometries and faster finishing.

- Production-quality parts: Tight tolerances, smooth surfaces, and excellent mechanical properties.

- Versatility: Ideal for prototypes, pilot runs, and low-volume production without investing in tooling.

MJF Technical Specifications

Capability | Specification |

|---|---|

Typical Tolerance | ±0.2 mm (±0.008 in); finer accuracy possible on small features |

Dimensional Accuracy | Up to ±0.1 mm for parts |

Minimum Feature Size | 0.5 mm (details such as thin walls or small holes should be ≥0.8 mm) |

Layer Thickness | 0.08 mm (80 microns) |

Surface Finish | Smooth gray finish; can be polished, dyed, or coated for cosmetics |

Build Volume | 380 × 284 × 380 mm (varies by machine model) |

Material Options | PA12, PA11, Glass-Filled Nylon, Carbon-Filled Nylon, Specialty powders |

Mechanical Properties | Tensile strength 48–50 MPa (PA12); elongation at break 15–20% |

Thermal Performance | Heat deflection temperature up to ~180 °C (depending on material grade) |

Production Volumes | From one-off prototypes up to thousands of units per run |

Lead Time | As fast as 2–5 business days, depending on batch size and finishing |

Available Materials for MJF

We provide a wide selection of industrial-grade nylon powders to meet different project needs.

Nylon PA12

Balanced mechanical properties and chemical resistance. A versatile choice for enclosures, connectors, and general-use functional parts.

Nylon PA11

More flexible and impact-resistant, with strong sustainability credentials (bio-based). Ideal for living hinges, snap fits, and consumer product prototypes.

PA12-GF

Reinforced with glass for higher stiffness and heat resistance. Commonly used in automotive housings, jigs, and load-bearing applications.

Specialty Options

Flame-retardant, ESD-safe, and custom powder grades available. Best for aerospace, electronics, and medical applications requiring certified materials.

Surface Finishes & Post-Processing

SLS printed parts come out strong and functional, but post-processing is often needed to achieve the right look and feel. We offer a range of finishing options to match your technical and cosmetic requirements.

Finish / Process | Description | Typical Use Case |

|---|---|---|

Standard Gray Finish | Uniform surface straight from the printer, functional with no extra steps. | Prototypes, functional testing, internal parts. |

Polishing / Vapor Smoothing | Improves surface smoothness, reduces roughness, enhances feel. | Cosmetic prototypes, consumer-facing components. |

Dyeing / Painting | Adds durable colors or custom coatings for branding and appearance. | Presentation models, pre-production samples. |

Coating | Specialized coatings for EMI shielding, waterproofing, or soft-touch feel. | Electronics housings, medical, and aerospace parts. |

Applications of MJF 3D Printing

Functional Prototypes

Produce prototypes with real engineering plastics like PA12 or PA11. These parts can handle stress, heat, and assembly testing, so you get accurate performance data before investing in tooling.

Low-Volume Production

MJF is ideal for bridge production or market launches. You can make hundreds or even a few thousand parts with consistent quality — all without waiting months for injection molds.

End-Use Components

Durable MJF parts are used directly in automotive ducts, aerospace brackets, and electronic housings. They deliver strength and repeatability while keeping lead times short.

Customized Products

Because there’s no tooling, customization comes at no extra cost. Perfect for medical braces, consumer products, or short-run items where each design may vary.

Why Choose MJF for Your Project?

Superior Accuracy

MJF achieves tight tolerances and excellent repeatability, so every batch matches your CAD design. This is critical when parts must fit into assemblies without secondary machining.

Strong Mechanical Properties

Parts have isotropic strength — consistent in all directions — unlike many 3D printing methods. That makes them suitable for snap-fits, housings, and functional components under real stress.

Excellent Surface Finish

The smooth gray surface straight from the printer reduces the need for heavy post-processing. When cosmetics matter, parts can be polished, dyed, or coated to match production-grade appearance.

Scalable Production

From one-off prototypes to a few thousand parts, MJF covers both prototyping and bridge production. You avoid tooling costs while still getting production-quality components.

Fast Lead Times

Typical turnaround is just 2–5 days. That speed helps you validate designs, run pilot builds, and meet tight launch schedules without delays.

Partner with Us for MJF 3D Printing Services

Our Equipment

CMM

Inspection

High Speed CNC Machines

Double-Head EDM Machines

EDM

Workshop

CNC machining Workshop

Plastic Injection Molding Room

Mirror EDM Machining

Mould Spotting Machine

Plastic Injection Team

Meet Our Expert Team: The Driving Force Behind TDL Mold’s Innovative Solutions.

Our Other 3D Printing Processes

We also offer a full range of additive manufacturing technologies to cover every need.

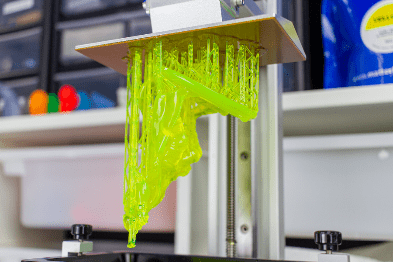

SLA uses a UV laser to cure liquid resin layer by layer, producing parts with exceptional surface finish and fine detail resolution.

- Appearance models and design reviews: parts look almost injection-molded

- Transparent components: can be polished to near-optical clarity

- Intricate geometries: sharp edges and thin walls are accurately reproduced

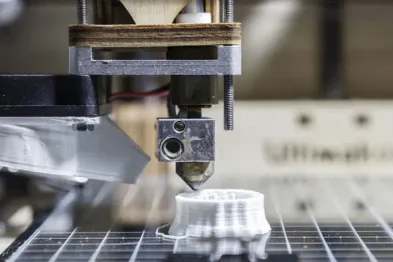

FDM builds parts by extruding molten thermoplastic layer by layer, making it one of the most cost-effective and widely used 3D printing processes.

- Functional prototypes made from engineering-grade plastics like ABS, ASA, or Nylon

- Large, durable parts with good strength for jigs, fixtures, and tooling

- Fast, affordable iterations early in the design cycle

SLS fuses nylon powder using a laser, building parts layer by layer without support structures. This makes it perfect for complex shapes and assemblies.

- Durable, functional prototypes for mechanical testing

- Snap-fit and moving assemblies thanks to excellent strength and flexibility

- Small-batch production without the cost of molds

FAQ's

MJF parts typically achieve ±0.3% of the nominal dimension, with a lower limit of ±0.2 mm. This level of accuracy is suitable for most functional prototypes and end-use parts. However, tolerances may vary depending on factors such as:

- Part size & geometry – Larger parts and thin-wall sections can show slightly more variation.

- Orientation & packing – How parts are placed in the build affects dimensional consistency.

- Post-processing – Steps like bead blasting, dyeing, or vapor smoothing may cause minor dimensional shifts.

For critical features like snap fits, mating parts, or press-fit components, it’s best to communicate requirements during the quoting stage so the design can be reviewed and, if needed, adjusted for higher precision.

Multi Jet Fusion (MJF) is most commonly associated with nylon-based powders, but material choices continue to expand. The main options include:

- PA 12 (Nylon 12): The most widely used MJF material. Offers excellent strength, fine detail, and chemical resistance. A great all-around choice for prototypes and production parts.

- PA 11 (Nylon 11): More ductile and impact-resistant than PA 12, making it suitable for snap fits, living hinges, and parts exposed to repeated stress.

- Glass-Filled PA 12: Reinforced with glass beads for improved stiffness and dimensional stability. Often used for housings, jigs, and fixtures.

- Polypropylene (PP): Provides chemical resistance and fatigue endurance, ideal for fluid-handling components or lightweight automotive parts.

- TPU (Thermoplastic Polyurethane): A flexible, rubber-like material for seals, gaskets, and impact-absorbing parts.

Specialty powders and color dyeing options are also available. If you have specific mechanical, cosmetic, or compliance requirements, it’s best to confirm material availability before starting the project.

MJF parts are surprisingly strong and durable for an additive manufacturing process, but they do not always match the performance of injection-molded components made from production-grade thermoplastics. Here’s what you should know:

- Mechanical Properties: MJF nylon (PA 12, PA 11) parts typically achieve tensile strengths of 45–50 MPa and elongation at break of 15–20%, which is sufficient for many functional end-use applications. Glass-filled grades can reach even higher stiffness, making them comparable to reinforced injection-molded plastics.

- Consistency: Unlike some 3D printing processes, MJF produces isotropic parts with consistent strength in all directions. This makes them more reliable than FDM or SLA when used for load-bearing or functional prototypes.

- Limitations: Injection-molded parts generally outperform MJF in terms of long-term fatigue, surface finish, and very high-volume repeatability. Molded parts also allow for a broader range of high-performance resins (e.g., PEEK, PC).

In practice, MJF is strong enough for jigs and fixtures, housings, brackets, and even production parts in industries like automotive and consumer electronics. If your design requires the highest possible mechanical strength and durability under continuous stress, injection molding is still the better long-term choice.

The build volume of an MJF machine defines the largest single part that can be produced in one run. Current industrial MJF printers, such as the HP Jet Fusion series, typically offer a maximum build size of around 380 x 284 x 380 mm (15 x 11.2 x 15 in).

- Single-Part Limitations: Any part larger than this envelope would need to be split into sections and bonded after printing. Our engineering team can advise on the best way to split and join oversized components while maintaining dimensional accuracy and mechanical strength.

- Batch Production: Even if your parts are smaller, the build chamber can be efficiently packed with multiple components in one run. This allows us to deliver hundreds of parts per build cycle with consistent quality and repeatability.

- Design Consideration: Keep in mind that nesting and orientation within the build chamber can affect surface quality and dimensional stability. A Design for Additive Manufacturing (DfAM) review is recommended before production to optimize part layout.

One of the biggest advantages of Multi Jet Fusion (MJF) is speed. Unlike traditional manufacturing or even some other 3D printing processes, MJF can produce functional parts in 1–3 business days once your design is finalized.

- Prototype Runs: For small batches or one-off prototypes, parts are often shipped in as little as 24–48 hours.

- Low-Volume Production: For orders ranging from dozens to hundreds of parts, lead times typically range from 3–5 business days, depending on part size, finishing requirements, and build chamber optimization.

- Scalability: Because MJF builds parts in a packed powder bed, multiple components can be printed in a single cycle, keeping turnaround fast even when production volumes grow.

If your project has a strict launch schedule, MJF is one of the best ways to move from CAD to usable parts quickly without compromising mechanical strength or accuracy.