FDM 3D Printing Service

Fast prototyping and low-volume production with industrial-grade FDM technology — get durable, functional parts delivered in as little as 2–3 days.

FDM 3D Printing Service

What is FDM 3D Printing?

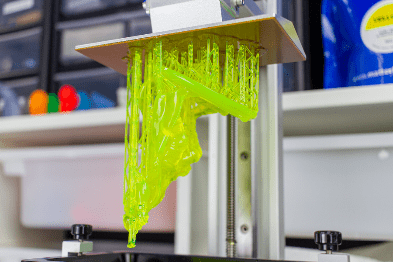

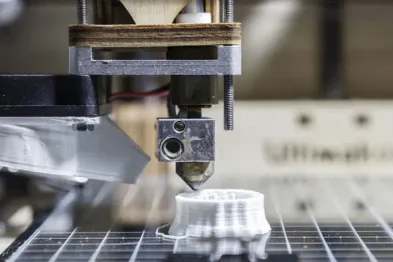

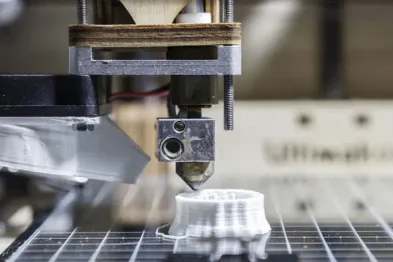

Fused Deposition Modeling (FDM) is one of the most widely used 3D printing technologies. It works by heating and extruding thermoplastic filament through a nozzle, depositing it layer by layer until your part is complete. This process is reliable, cost-effective, and ideal for producing functional prototypes and low-volume end-use parts.

FDM stands out for its affordability, material variety, and ability to print large, durable components. Whether you need a quick prototype to validate a design, a bridge-production run before tooling, or oversized fixtures and jigs, FDM is a proven choice that keeps development moving fast.

Fused Deposition Modeling Capabilities

Capability | Specification |

|---|---|

Build Volume | Up to 914 × 610 × 914 mm (36 × 24 × 36 in) — print large parts in one piece, reduce assembly time |

Layer Thickness | 0.127 – 0.330 mm (0.005 – 0.013 in) — choose fine layers for detail or thicker layers for speed |

Typical Tolerances | ±0.2 mm or ±0.002 mm/mm — accurate enough for jigs, fixtures, and functional prototypes |

Materials Available | ABS, ASA, Nylon 12, PC, ULTEM™, and more — engineering-grade thermoplastics for real-world testing |

Infill Options | Solid or sparse infill — balance strength, weight, and cost for your application |

Post-Processing | Support removal, light sanding, painting, or machining — get parts ready for use or presentation |

Production Volumes | From single prototypes to dozens of parts — scalable without tooling investment |

For large assemblies, we can optimize build orientation and part splitting to minimize warpage and maximize strength in the load direction.

Materials We Support

FDM 3D printing supports a wide range of engineering-grade thermoplastics, allowing you to match the right material to your project’s strength, durability, and cost requirements.

Material | Key Properties | Typical Applications |

|---|---|---|

ABS | High strength, good heat resistance, easy post-processing | Functional prototypes, housings, enclosures |

ASA | UV and weather resistant, good dimensional stability | Outdoor components, automotive parts |

Nylon (PA6, PA12) | Excellent toughness, wear resistance | Gears, jigs, fixtures, and moving assemblies |

PC (Polycarbonate) | High impact strength, temperature resistant | Industrial components, lighting housings |

CF-PLA / CF-Nylon | Carbon fiber reinforced, stiff and lightweight | Structural parts, end-use fixtures |

Post-Processing & Finishing Options

FDM parts can be functional right off the printer, but post-processing can enhance their appearance, durability, and fit for final use.

Process | What It Does | Best For |

|---|---|---|

Sanding & Polishing | Removes layer lines and smooths surfaces | Cosmetic parts, presentation models |

Painting & Coating | Adds color and surface protection | Consumer products, branded prototypes |

Chemical Smoothing (e.g., Vapor Polishing)

| Dissolves surface layer slightly for glossy finish | ABS parts requiring improved aesthetics |

Tapping & Threaded Inserts | Adds functional threads or brass inserts | Assembly-ready parts and fixtures |

You can also request before-and-after photos or finishing samples to set expectations before production.

Applications of FDM 3D Printing

Functional Prototypes

Print accurate, durable prototypes to check fit, function, and ergonomics before committing to expensive tooling. Catching design issues early saves time and prevents costly rework.

Low-Volume Production

Bridge the gap between prototyping and full-scale manufacturing. FDM is ideal for small batches and on-demand production runs, avoiding the lead time and cost of injection mold tooling.

Jigs, Fixtures, and Tooling

Create custom workholding fixtures, assembly aids, and inspection tools with strong thermoplastics. Well-designed fixtures improve safety, speed up assembly, and maintain quality consistency.

Large-Format Models

Take advantage of FDM’s large build volumes to produce architectural models, trade show displays, or oversized functional components in one piece, reducing the need for assembly.

Why Choose Us

Industrial-Grade FDM Printers

We run professional production machines with large build volumes, delivering consistent quality and repeatability for prototypes and end-use parts alike.

Free DFM Review

Our engineers check your files before printing, optimize part orientation, and adjust support strategy to ensure better strength, surface finish, and cost efficiency.

ISO-Certified Quality

Every batch is inspected for dimensional accuracy and consistency. Our processes follow ISO quality standards, so you get parts you can rely on.

Dedicated Support Team

From quoting to delivery, our team is available to answer questions, suggest design tweaks, and make sure you get the right parts the first time.

Partner with Us for FDM 3D Printing Services

Our Equipment

CMM

Inspection

High Speed CNC Machines

Double-Head EDM Machines

EDM

Workshop

CNC machining Workshop

Plastic Injection Molding Room

Mirror EDM Machining

Mould Spotting Machine

Plastic Injection Team

Meet Our Expert Team: The Driving Force Behind TDL Mold’s Innovative Solutions.

Our Other 3D Printing Processes

We also offer a full range of additive manufacturing technologies to cover every need.

SLA uses a UV laser to cure liquid resin layer by layer, producing parts with exceptional surface finish and fine detail resolution.

- Appearance models and design reviews: parts look almost injection-molded

- Transparent components: can be polished to near-optical clarity

- Intricate geometries: sharp edges and thin walls are accurately reproduced

SLS fuses nylon powder using a laser, building parts layer by layer without support structures. This makes it perfect for complex shapes and assemblies.

- Durable, functional prototypes for mechanical testing

- Snap-fit and moving assemblies thanks to excellent strength and flexibility

- Small-batch production without the cost of molds

MJF takes powder-bed printing further by using fusing agents and infrared energy for uniform mechanical properties and faster production cycles.

- Short-run production where part consistency matters

- Complex geometries with fine details and smooth, semi-matte finish

- Economical per-part cost at higher volumes compared to SLS

FAQ's

FDM 3D printing supports a wide range of engineering-grade thermoplastics. The most common options include:

- ABS: Strong, heat-resistant, and easy to post-process; great for functional prototypes and housings.

- ASA: UV- and weather-resistant, making it ideal for outdoor parts and automotive applications.

- Nylon (PA6, PA12): Tough, wear-resistant, and suitable for moving assemblies like gears or jigs.

- PC (Polycarbonate): High-impact strength and heat resistance for industrial components.

- Carbon-Filled Composites: Lightweight, stiff, and excellent for structural or tooling applications.

If you’re not sure which material is right for your part, send us your CAD file. Our engineers can recommend the best option based on strength, temperature resistance, and budget.

With industrial-grade FDM printers, we can produce parts up to 914 × 610 × 914 mm (36 × 24 × 36 in) in a single build. This large build volume allows you to print oversized prototypes, jigs, and end-use components without splitting them into multiple pieces.

If your part is larger than the maximum build size, we can section it into smaller parts, print them individually, and bond them together with minimal visible seams. This approach is useful for full-scale models, trade show displays, and very large functional parts.

Typical dimensional accuracy for FDM 3D printed parts is ±0.2 mm or ±0.5% of the nominal dimension (whichever is greater) on well-supported features. This is sufficient for most functional prototypes, fixtures, and low-volume production parts.

Several factors can influence accuracy, including material shrinkage, part geometry, print orientation, and thermal expansion during the build. For critical dimensions such as mating holes or sealing surfaces, we can adjust part orientation or add post-machining to meet tighter tolerances.

If your project has demanding accuracy requirements, send us your CAD file. Our team can review it and recommend the best approach to balance precision, cost, and lead time.

Prototype FDM parts can typically ship in as little as 2–3 business days once your design is confirmed. For low-volume production runs, lead times are usually 5–7 business days, depending on part size, quantity, and finishing requirements.

If you’re working against a tight deadline, we offer expedited printing and shipping options. Let us know your target delivery date when requesting a quote, and we’ll prioritize your order to keep your project on schedule.

FDM parts are durable and suitable for functional testing, jigs, fixtures, and even end-use applications — but they are generally not as strong or isotropic as injection-molded parts. Because FDM builds parts layer by layer, strength is slightly lower in the Z-axis (layer-to-layer direction) compared to the X-Y plane.

You can improve part strength by:

- Optimizing Print Orientation: Aligning the part so that critical features carry loads in the strongest direction.

- Increasing Wall Thickness or Infill Density: Adding more material where strength matters most.

- Choosing Engineering-Grade Materials: Nylon, PC, and carbon-filled composites offer better mechanical performance.

If you need injection-molded strength for production, FDM is still a great way to prototype and validate your design before investing in tooling. Our team can also suggest modifications to get the most strength possible from your FDM parts.

Yes. We take confidentiality seriously and can sign a Non-Disclosure Agreement (NDA) before reviewing your CAD files. All files you share with us are stored securely, accessed only by the engineers working on your project, and permanently deleted upon request.

Our quoting and production systems are designed with data security in mind, so you can confidently share designs for prototypes, fixtures, or production parts knowing your intellectual property is protected.