From Manufacturing to Delivery: Ensuring Quality Across the Supply Chain

Quality doesn’t stop at the end of production. For injection molding projects, every stage after manufacturing — from inspection and packaging to shipping and customs

Learn from the leader in plastic mould manufacturing and injection molding worldwide.

Quality doesn’t stop at the end of production. For injection molding projects, every stage after manufacturing — from inspection and packaging to shipping and customs

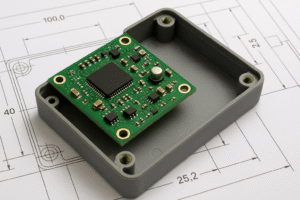

In modern product development, the boundaries between electronics and mechanical design are rapidly disappearing. A printed circuit board (PCB) no longer exists in isolation—it must

CNC turning and CNC milling are often mentioned together — they are two of the most widely used machining processes in modern manufacturing. Both rely

If you’ve ever tried to design a part that needs two materials or colors, you’ve probably come across both two shot injection molding and overmolding.

When you’re designing a part that needs two materials or colors in one piece, you quickly run into a decision: do you assemble separate components

CNC milling is one of the most efficient ways to turn a CAD design into a precise, functional part. The process uses computer-controlled rotary cutters

CNC turning is one of the most widely used machining processes for producing precise cylindrical components. By rotating the workpiece at controlled speeds and applying

Bringing a new product to market often stalls at one critical step — getting small batches of parts that match production quality. Traditional injection molds

Delays in tooling can derail even the best-planned projects. When production molds take months to complete, schedules slip, and market opportunities may be lost. Rapid

Inventory management involves overseeing and controlling a company’s stock, storing, ordering, and selling goods and services. Therefore, businesses today that have incorporated inventory management are

In various Industries, including manufacturing, there are several professionals charged with ensuring that when a product comes in as raw material and leaves as a

In mechanical engineering, accuracy and precision are crucial. Therefore, understanding the principles of tolerance, including reading and interpreting tolerance Charts, leads to a successful product

Send us a Email, we will feedback to you ASAP!