The Complete Guide to Mold Temperature Controller

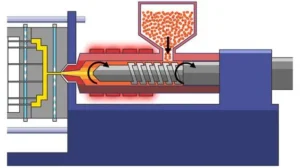

The mold temperature plays a crucial role in determining the cycle duration and part quality while producing plastic injection-molded parts. Thus, maintaining ideal temperature control

Learn from the leader in plastic mould manufacturing and injection molding worldwide.

The mold temperature plays a crucial role in determining the cycle duration and part quality while producing plastic injection-molded parts. Thus, maintaining ideal temperature control

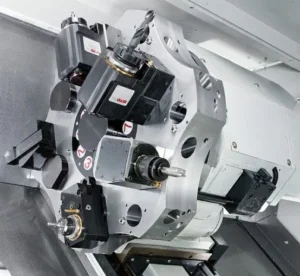

Dive into the world of tool turrets, the revolutionary component in CNC machines that enhances efficiency, reduces setup times, and ensures high-quality machining.

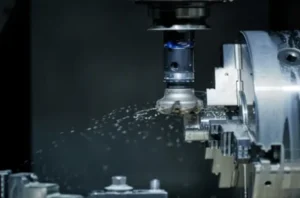

Milling is an all-round machining process which can be applied to various materials including metals, plastics and composites. The suitability of a material for milling

Unlock the potential of polypropylene injection molding with our in-depth guide. From material properties to the molding process and practical applications, discover everything you need to know.

Dive into the complexities of injection molding cost estimation. Learn how to navigate through equipment, mold, material, and labor costs to accurately budget your project.

Discover key techniques for minimizing scrap in mold manufacturing, driving cost savings, improving quality, and ensuring a more sustainable production process.

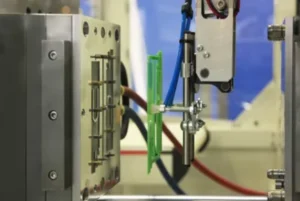

Connecting wires using a wire nut can seem like a walk in the park. But the truth is this: a single mistake can quickly escalate the process turning it into a disaster.

Wire nuts are plastic electrical devices shaped in the form of a miniature cup but used to safely and securely connect two or more electrical wires. They have a metal core that helps in effectively screwing the wires tightly together.

Embracing sustainability is even more pressing on plastic injection manufacturers as they have applications across several industries where their influence is significant.

Throughout American history, the manufacturing industry has undergone continuous innovation, from the Industrial Revolution’s introduction of water and steam power to the era of mass production driven by electrical power and assembly line manufacturing. In the late 20th century, the integration of IT systems and automation reshaped industry dynamics.

Injection molding is a whirlwind sweeping other industries off their feet with innovative methods and technologies that have continued to improve and pay dividends in product design and manufacturing. At the center of these innovations is the U.S. injection molding industry steering the ship of this industry for others to follow.

Process control in mold manufacturing refers to the management and oversight of various production processes involved in injection molding. It incorporates implementing measures to ensure

Send us a Email, we will feedback to you ASAP!