SLS 3D Printing Service

Get production-grade nylon prototypes and end-use parts with selective laser sintering (SLS). Fast turnaround in 3–7 days, complex geometries without supports, and durable material options for functional testing or small-batch production.

SLS 3D Printing Service

What is SLS 3D Printing?

Selective Laser Sintering (SLS) is an industrial 3D printing process that builds parts by fusing nylon powder layer by layer with a high-power laser. Because the surrounding powder naturally supports the part during printing, no extra support structures are required. It is suitable for:

- Complex Geometries

- Functional Prototypes

- Low-Volume Production

Selective Laser Sintering Capabilities

Capability | Specification |

|---|---|

Maximum Build Size | 300 × 300 × 300 mm (single build, larger parts can be split and assembled) |

Minimum Wall Thickness | 0.8 – 1.0 mm (depending on geometry and part size) |

Layer Thickness | 0.1 – 0.12 mm |

Dimensional Accuracy | ±0.2 mm or ±0.3% of part size (whichever is greater) |

Surface Finish | Matte, slightly grainy (typical of nylon powder sintering) |

Density of Parts | ~95% of injection-molded nylon |

Mechanical Properties | Nylon PA12: tensile strength 45–50 MPa, elongation at break 15–20% |

Heat Resistance | Heat deflection temperature ~170 °C (depending on material grade) |

Supported Materials | Nylon PA12, PA11, glass-filled nylon, carbon-filled nylon |

SLS Materials We Offer

We provide a wide selection of industrial-grade nylon powders to meet different project needs.

Nylon PA12

The most widely used SLS material. Excellent dimensional stability, good surface quality, and balanced mechanical strength. Ideal for prototypes, enclosures, and general-use functional parts.

Nylon PA11

More flexible and impact-resistant than PA12, with superior chemical resistance. Suitable for living hinges, clips, and components exposed to oils or chemicals.

PA12-GF

Reinforced with glass beads for higher stiffness and improved heat resistance. A good choice for structural housings and parts that must maintain shape under load.

PA12-CF

Lightweight with high rigidity and strength-to-weight ratio. Commonly used for aerospace, automotive, and performance applications where weight reduction is critical.

Surface Finishes & Post-Processing

SLS printed parts come out strong and functional, but post-processing is often needed to achieve the right look and feel. We offer a range of finishing options to match your technical and cosmetic requirements.

Finish / Process | Description | Typical Use Case |

|---|---|---|

Depowdering & Deburring | Removal of loose powder and sharp edges to ensure accuracy and safe handling. | Standard step for all functional parts. |

Sanding & Polishing | Smooths surface, improves appearance, and prepares parts for painting. | Prototypes requiring cosmetic quality. |

Dyeing | Nylon parts can be dyed in multiple colors with durable, uniform results. | Branding, colored prototypes, or end-use parts. |

Painting & Coating | Adds custom colors or protective layers for a production-like finish. | Trade show models, pre-production prototypes. |

Special Treatments | Includes sealing, texturing, or plating for enhanced performance or look. | Parts needing specific surface effects or durability. |

Applications for Selective Laser Sintering

SLS 3D printing is widely used across industries because it combines design freedom with functional strength.

Functional Prototypes

SLS nylon parts withstand stress, heat, and chemical exposure — letting you test assemblies under realistic conditions. For example, engineers often use SLS housings to check snap fits and vibration resistance before committing to costly injection molds.

Low-Volume Production

When you need a few dozen to a few hundred parts, SLS bridges the gap without tooling investment. It’s common for startups to launch pilot batches with SLS, reducing time-to-market while preparing for full-scale production.

Complex Geometries

Because no supports are required, SLS excels at internal channels, lattice structures, and organic designs that traditional machining or molding can’t achieve. This makes it ideal for lightweight aerospace brackets or fluid-handling components with hidden passages.

End-Use Components

Durable nylon materials make SLS parts reliable enough for real-world use. Automotive suppliers, for example, often run SLS clips, ducts, or interior components directly in vehicles for field testing or limited series production.

Advantages of SLS 3D Printing

No Support Structures Needed

Unlike FDM or SLA, SLS parts are supported by unsintered powder during the build. This means you can design internal channels, lattice structures, and complex undercuts without worrying about removing fragile support material later. For customers, this translates to greater design freedom and less post-processing cost.

Strong, Functional Materials

SLS uses industrial-grade nylon powders (PA11, PA12, glass-filled, carbon-filled) that deliver high impact resistance, chemical stability, and durability under stress. Engineers rely on these parts for real-world functional testing — not just visual mockups — because the material performance is close to molded thermoplastics.

Design Freedom

The process allows intricate geometries that traditional machining or molding cannot achieve. For example, lightweight lattice structures reduce part weight without sacrificing strength, a critical advantage in aerospace brackets or medical devices.

Scalable for Low-Volume Production

Whether you need 20 prototypes or 1,000 end-use parts, SLS maintains consistent quality across batches. Many companies use it for bridge production, ensuring assembly lines keep running while waiting for mass-production tooling. This scalability reduces supply chain risk and keeps projects on schedule.

Cost Efficiency

Since SLS doesn’t require steel tooling, upfront costs are much lower compared to injection molding. It also minimizes material waste because unused powder is recyclable. For projects that only need limited quantities, this makes SLS one of the most economical choices.

Fast Turnaround

Typical lead times are 3–5 days from file to finished part, compared to weeks or months for tooling-based methods. This speed helps teams iterate quickly, validate design changes, and accelerate time-to-market — a decisive factor in competitive industries like consumer electronics.

Partner with Us for SLS 3D Printing Services

Our Equipment

CMM

Inspection

High Speed CNC Machines

Double-Head EDM Machines

EDM

Workshop

CNC machining Workshop

Plastic Injection Molding Room

Mirror EDM Machining

Mould Spotting Machine

Plastic Injection Team

Meet Our Expert Team: The Driving Force Behind TDL Mold’s Innovative Solutions.

Our Other 3D Printing Processes

We also offer a full range of additive manufacturing technologies to cover every need.

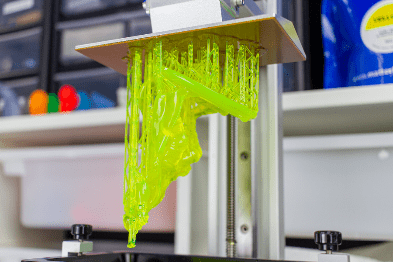

SLA uses a UV laser to cure liquid resin layer by layer, producing parts with exceptional surface finish and fine detail resolution.

- Appearance models and design reviews: parts look almost injection-molded

- Transparent components: can be polished to near-optical clarity

- Intricate geometries: sharp edges and thin walls are accurately reproduced

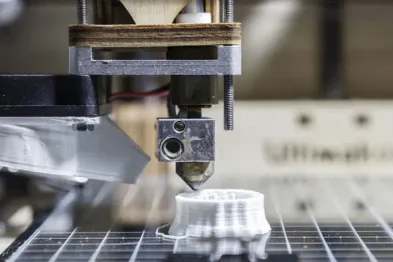

FDM builds parts by extruding molten thermoplastic layer by layer, making it one of the most cost-effective and widely used 3D printing processes.

- Functional prototypes made from engineering-grade plastics like ABS, ASA, or Nylon

- Large, durable parts with good strength for jigs, fixtures, and tooling

- Fast, affordable iterations early in the design cycle

MJF takes powder-bed printing further by using fusing agents and infrared energy for uniform mechanical properties and faster production cycles.

- Short-run production where part consistency matters

- Complex geometries with fine details and smooth, semi-matte finish

- Economical per-part cost at higher volumes compared to SLS

FAQ's

For Selective Laser Sintering (SLS), the typical tolerance you can expect is around ±0.2 mm (±0.008 in) for most geometries.

- On small features, accuracy is usually better, often within ±0.1 mm.

- On larger parts, tolerance can vary more because of thermal effects and powder spreading.

- Factors like part orientation, wall thickness, and post-processing also influence the final accuracy.

In practice, if your design includes critical dimensions, it’s best to:

- Run a DFM (Design for Manufacturability) review before production.

- Add allowances for shrinkage or finishing.

- Consider secondary machining for tight-tolerance features (e.g., holes, threads).

So while SLS gives excellent accuracy for prototypes and end-use parts, it’s not the best choice for ultra-precise fits (e.g., aerospace-grade press fits) without post-machining.

For SLS 3D printing, the most common materials are nylon-based powders, because they combine durability, flexibility, and heat resistance. Typical options include:

- Nylon PA12: The standard choice; strong, stable, and with good surface finish.

- Nylon PA11: More flexible and impact-resistant, ideal for living hinges and snap fits.

- Glass-Filled Nylon (PA12-GF): Stiffer and more heat-resistant, used for housings and load-bearing parts.

- Carbon-Filled Nylon (PA12-CF): Lightweight with high rigidity, suitable for aerospace or automotive components.

Other specialty powders are also available (e.g., flame-retardant, ESD-safe grades), depending on your application needs.

SLS parts are highly durable compared to most other 3D printing methods. Because they’re made from nylon powders (PA11, PA12, and composites), they deliver:

- Mechanical strength: Tough enough for snap fits, load-bearing housings, and structural prototypes.

- Thermal and chemical resistance: Nylon grades withstand moderate heat and exposure to oils or solvents, making them suitable for functional testing.

- Long-term use: Many customers use SLS parts directly in automotive, aerospace, and consumer products for end-use applications.

That said, they’re not as long-lasting as injection-molded thermoplastics. Over very high stress, prolonged outdoor exposure, or extreme heat, performance can degrade faster. For mission-critical parts, secondary machining or switching to injection molding may be the better path.

For quoting and file submission, we typically accept all standard 3D CAD formats:

- STEP (.step / .stp): Preferred for quoting and manufacturing.

- IGES (.iges / .igs): Widely used for CAD data exchange.

- STL (.stl): Common for 3D printing, though it only contains mesh data (no parametric features).

Other formats can often be converted, but for the fastest and most accurate quoting, STEP or IGES is best.