Insert Molding Services

Seamless integration of metal, electronics, or custom inserts into precision-molded plastic parts.

- In-house mold design & manufacturing

- ISO 9001 / ISO 13485 certified

- Tooling and sampling in as fast as 2 weeks

What Is Insert Molding?

Insert molding is a manufacturing process where a metal, threaded insert, or electronic component is pre-placed into a mold and then overmolded with plastic during a single injection molding cycle.

This technique creates a strong mechanical bond between the insert and the plastic, eliminating the need for secondary assembly steps like pressing, soldering, or gluing.

It’s widely used to save production time, reduce costs, and enhance structural reliability in complex parts.

- Medical connectors

- Automotive terminals

- Plastic-sealed sensors and PCB housings

TDL’s Insert Molding Capabilities

With more than 20+ years of precision molding experience, TDL delivers insert molding solutions that combine engineering-grade plastics with metal or electronic inserts — all with tight process control and production flexibility.

Capability Item | Specification / Scope |

|---|---|

Supported Insert Types | Metal pins, threaded bushings, contacts, terminals, magnets, sensors, custom hardware |

Insert Positioning | Manual loading, semi-automatic placement, or robotic alignment for high consistency |

Max Part Dimensions | Up to 300 × 300 × 120 mm (11.8 × 11.8 × 4.7 in.) |

Precision Tolerance | ±0.02 mm insert alignment; suitable for electrical, structural, or sealing-critical designs |

Insert-to-Resin Materials | Brass, stainless steel, aluminum + ABS, PC, Nylon, PBT, PC/ABS, PP |

Mold Types | Single-cavity, multi-cavity, and family molds supported; in-house mold design & build |

Production Volume | From 100 units to 100,000+ parts per year |

Tooling Lead Time | Mold fabrication and T0 sampling as fast as 2–3 weeks |

Validation Process | T0, T1, T2 sample trials; dimensional inspection; bonding strength verification |

Applications | Automotive connectors, medical components, smart devices, wearables, and industrial housings |

Materials for Insert Molding

Common Insert Materials

Brass

Excellent machinability and conductivity; ideal for threaded inserts and terminals

Stainless Steel

Corrosion-resistant and durable; often used in medical and structural components

Aluminum

Lightweight and conductive; used for EMI shielding or lightweight mechanical assemblies

Copper

High electrical conductivity; suitable for electronic terminals

Magnets

Embedded electronics, RFID chips, ceramic components, etc.

Thermoplastic Resins We Mold Around Inserts

ABS

Rigid, cost-effective, and easy to mold

PC

High impact strength and heat resistance

Nylon

Tough, wear-resistant, ideal for load-bearing parts

PBT

Excellent dimensional stability and insulation properties

PC/ABS Alloy

Balanced toughness and flow characteristics

PP

Lightweight and chemical-resistant

Other engineered resins are available upon request

Not sure which materials suit your insert application? Our team can help you evaluate bonding compatibility, temperature resistance, and mechanical fit.

Our Injection Molding Process

Material Selection

Choosing the appropriate plastic material is the initial step. This involves consideration of factors such as the product's intended use, environmental conditions, durability, and cost. The selected material impacts the performance, lifespan, and functionality of the final product.

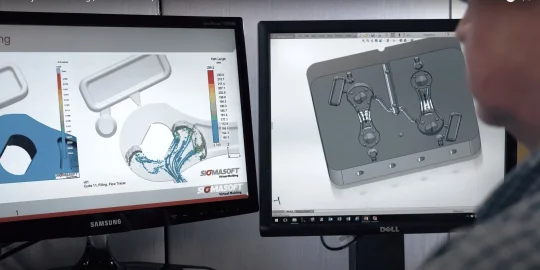

Mold Creation

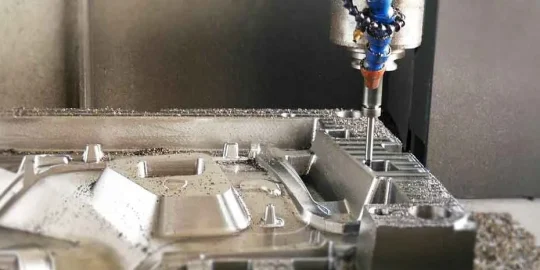

The next step involves designing and creating the mold based on the product specifications. High-quality stainless steel is often used due to its durability and resistance to wear. The mold's design is guided by the SPI-SPE standards, ensuring precision and consistency in the produced parts.

Injection Process

The selected plastic material is heated and injected into the mold under high pressure. This stage requires careful control of conditions like temperature, pressure, and injection speed to ensure the material fills the mold uniformly and solidifies correctly, maintaining the design's integrity.

Cooling and Ejection

After injection, the mold is cooled to allow the plastic to harden into the desired shape. Once adequately cooled, the final product is ejected from the mold. This step includes any necessary post-processing services such as trimming, surface finishing, and assembly to ensure the product meets all specifications and quality standards.

Why Choose TDL Mould for Insert Molding Services

TDL delivers high-performance insert molded parts, from prototyping to mass production.

In-House Tooling & Mold Design

All molds are designed and manufactured in-house, enabling full control over lead times, quality, and mold modifications. We support single-cavity, multi-cavity, and complex insert layouts.

Precision Insert Placement

With manual, semi-automatic, and robotic insert positioning options, we achieve ±0.02 mm alignment accuracy — critical for electrical contacts, threaded inserts, and structural components.

Fast Lead Times & Scalable Production

Rapid mold fabrication (as fast as 2–3 weeks) and flexible batch sizes from 100 to 100,000+ parts/year. Perfect for both pilot runs and full-scale production programs.

Engineering Support

Our team collaborates on DFM, insert orientation, gate placement, and bonding optimization. We help prevent common insert molding issues before tooling even begins.

Broad Insert & Resin Compatibility

We handle a wide range of inserts — brass, stainless steel, copper, magnets, sensors — combined with engineering-grade resins like ABS, PC, Nylon, and PBT.

Certified Quality Assurance

TDL is ISO 9001 and ISO 13485 certified. Every project includes dimensional inspections, FAI samples, and process traceability to ensure consistent results.

From functional prototypes to precision assemblies, TDL delivers insert molding solutions built for strength, reliability, and manufacturability.

Overmolding Service Process

Project Evaluation

We review your 2D/3D files and application requirements to assess feasibility, insert compatibility, and risk points.

DFM & Quotation

Our engineers provide Design for Manufacturability (DFM) feedback and issue a detailed quotation covering tooling, lead time, and production cost.

Mold Design & Insert Strategy

We develop in-house tooling with optimized insert placement, gate location, and alignment features — tailored to your part function and volume.

Tooling & T0–T2 Sampling

We fabricate molds and run initial sample trials (T0, T1, T2) for dimensional verification, bonding evaluation, and client approval.

Mass Production

Once samples are approved, we move to full-scale production with process monitoring, insert traceability, and quality inspections.

Packaging & Global Delivery

Parts are packed per your requirements and shipped worldwide with documentation, labeling, and logistics coordination handled by our team.

After-Sales Support

Offer after-sales support, clients can request technical assistance.

Need to start small? We also support pilot runs and bridge tooling to help you launch faster.

We support CAD, STL, STEP, and IGES formats. Contact us if you encounter any upload issues.

Common Applications of Insert Molding

Insert molding is widely used across industries that demand strong mechanical bonds, precise alignment, or integrated electrical functionality. At TDL, we support a broad range of use cases, backed by over 20 years of proven process expertise.

- Wire harness connectors

- Sensor housings

- Threaded mounts in plastic brackets

- Anti-vibration inserts in dashboards

- Handheld instrument housings with metal reinforcement

- Catheter hubs with embedded needles or ports

- Wearable monitoring device shells

- USB ports and jack housings

- Device enclosures with metal frames

- Battery compartments with terminals

Industrial Equipment

- Overmolded switches or circuit connectors

- Structural parts with bushings or shafts

- Embedded magnets in automation components

Smart Products & IoT

- Embedded sensors in wearables

- RFID tag casings

- Smart lock housings with conductive inserts

Have a unique application in mind? Share your design with us — we’ll help you evaluate feasibility and optimize for production.

Choose us for insert molding services and get up to 100% mould cost refund!

Our Equipment

CMM

Inspection

High Speed CNC Machines

Double-Head EDM Machines

EDM

Workshop

CNC machining Workshop

Plastic Injection Molding Room

Mirror EDM Machining

Mould Spotting Machine

Plastic Injection Team

Meet Our Expert Team: The Driving Force Behind TDL Mold’s Innovative Solutions.

Our Related Services & Capabilities

At TDL, we design molds with a clear focus on manufacturability, durability, and efficiency. Our team combines advanced CAD/CAM tools, mold-flow simulation, and hands-on production experience to anticipate issues before cutting steel. Through flow analysis and DFM reviews, we identify risks such as short shots or warpage early, saving you from costly rework and ensuring the mold runs reliably from the start.

TDL builds molds that hold up in real production. We use high-grade steel, precision machining, and strict QC to make sure every tool matches the design intent. From prototype molds to multi-cavity production tools, we control tolerances, surface finish, and cooling layouts so parts come out consistent and cycle times stay efficient. Each mold is tested before shipment, giving you tools that are ready to run and reliable over the long term.

TDL runs 75+ injection molding machines from 50 to 3,700 tons, giving you flexibility from small prototype runs to full-scale production. We support single-cavity, multi-cavity, and family molds, with part-to-part repeatability down to ±0.004 mm. You can get T1 samples in as fast as 2 weeks, with no MOQ required. Our ISO-certified facilities, including cleanroom molding, ensure consistent quality for industries such as medical, automotive, and consumer electronics.

At TDL, we offer a full range of surface finishing options, from polishing and texturing to painting, plating, and laser marking. These processes improve function, durability, or aesthetics, depending on your application. Whether you need a high-gloss surface for consumer products or a textured finish for better grip, we deliver consistent, production-ready results directly from our shop floor.

FAQ's

A wide variety of inserts can be used in injection molding, depending on the application. At TDL, we commonly work with:

- Threaded inserts (e.g., brass bushings or stainless-steel nuts)

- Metal pins and shafts for alignment or rotation

- Electrical terminals and contact points

- Magnets and sensors for smart components

- RFID tags, PCBs, and microelectronic modules

- Custom machined or stamped metal parts

Inserts can be supplied by the customer or sourced by us, and we support both standard and highly specialized insert configurations.

We offer flexible options based on your project needs:

- Standard inserts (such as threaded bushings, pins, and terminals) can be sourced by TDL through our trusted supplier network.

- Custom or proprietary inserts (e.g., sensors, PCBs, magnets) are typically supplied by the customer to ensure exact specifications.

If needed, we’re happy to assist with insert sourcing, qualification, and testing to ensure compatibility with the molding process.

Not sure which inserts to use? Our engineering team can help evaluate material, geometry, and placement feasibility.

Our insert placement process achieves high precision alignment, with typical tolerances of:

- ±0.02 mm for critical dimensions (e.g., electrical contacts, threaded inserts)

- ±0.05 mm for general insert locations

We use manual, semi-automatic, or robotic insert loading depending on part geometry, volume, and tolerance requirements. Fixtures and tooling are carefully designed to ensure consistent positioning throughout production.

For applications requiring ultra-tight tolerances, we also offer process validation, pin location verification, and FAI reports.

We work with a wide range of engineering-grade thermoplastics to meet structural, thermal, and electrical requirements. Common resins used in insert molding include:

- ABS: Rigid, easy to mold, suitable for housings and covers

- Polycarbonate (PC): High impact resistance and heat stability

- Nylon (PA6, PA66): Tough and wear-resistant, ideal for load-bearing parts

- PBT: Excellent dimensional stability and electrical insulation

- PC/ABS: Balanced toughness and flow characteristics

- Polypropylene (PP) : Lightweight and chemically resistant

Need a specific resin for your application? We can help select the best material for your insert and performance requirements.

Tooling and sampling timelines depend on part complexity, insert type, and production requirements. At TDL, we offer fast and predictable turnaround:

- Tooling fabrication: typically 2–4 weeks

- T0–T2 sampling: usually delivered within 3–5 days after mold completion

- Urgent projects: expedited options available upon request

We provide clear timelines during the quoting stage and keep you informed throughout the process, from DFM to mold approval.

Need to accelerate development? Ask us about fast-track tooling programs.

Yes! Our engineering team provides full design support throughout your insert molding project.

We help ensure your part is optimized for functionality, manufacturability, and insert integration.

Our design assistance includes:

- DFM (Design for Manufacturability) analysis

- Insert layout and orientation guidance

- Gate and parting line optimization

- Material and bonding recommendations

- Support for CAD modifications and revisions

Whether you're starting from a concept or refining an existing design, we collaborate to improve moldability, reduce risk, and accelerate development.

Send us your 2D/3D files — we’ll provide expert feedback at no extra cost.

Yes, TDL is fully certified to international quality standards.

Our insert molding processes are supported by robust quality systems to ensure consistent, traceable, and compliant production.

We maintain the following certifications:

- ISO 9001:2015 – Quality Management System

- ISO 13485 – Medical device manufacturing (available upon request)

We also support:

- FAI (First Article Inspection)

- PPAP (Production Part Approval Process)

- RoHS / REACH compliance

- Material and batch traceability

Need documentation for regulated industries? We provide full quality reports upon request.