The Complete Guide to Injection Molding Simulation Software

Injection molding stands as the foundation of the manufacturing world, revolutionizing the production of parts across a myriad of industries. This method, known for its

Learn from the leader in plastic mould manufacturing and injection molding worldwide.

Injection molding stands as the foundation of the manufacturing world, revolutionizing the production of parts across a myriad of industries. This method, known for its

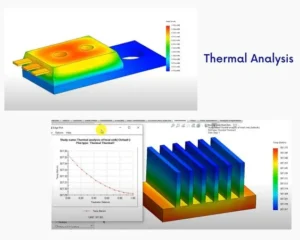

Thermal stress analysis is a process used to evaluate the effects of temperature changes on the structural integrity of a part. It involves simulating how

You’ve finalized the part design—but once it enters tooling, problems begin: short shots, warpage, uneven filling. Sound familiar? These issues often trace back to one

Looking for a reliable plastic injection molding company near you? Whether you’re launching a new product or scaling production, choosing the right manufacturing partner is

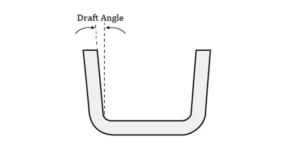

Introduction to Draft in Injection Molding When designing parts for injection molding, it is essential to incorporate draft angles to ensure smooth part removal from

Introduction Brass is a top material for CNC machining, a subtractive manufacturing process using computer controls. It involves cutting away material from a solid brass

Introduction to Gundrilling Gun drilling is an exceptional manufacturing technique designed to produce deep, accurate holes in metals. It is critical for industries that demand

Introduction Overmolding and insert molding are key manufacturing techniques used to produce high-quality plastic products by combining different materials for better function, comfort, and appeal.

Introduction Metal 3D printing is an additive manufacturing technology used to create metal parts directly from computer designs. Metal 3D printers work by building layers

Thermoplastic Elastomer (TPE) is widely used to make various products. This material, introduced in the 1960s, is a combination of materials with thermoplastic and elastomeric

Acrylonitrile Butadiene Styrene (ABS) is one of the most commonly used plastics in manufacturing today—from LEGO bricks and automotive parts to kitchen appliances and medical

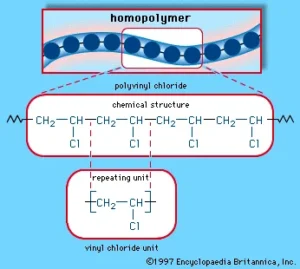

Polyvinyl chloride (PVC) is one of the most widely used synthetic polymers. Half of its content consists of chlorine. PVC is produced by polymerization of

Send us a Email, we will feedback to you ASAP!